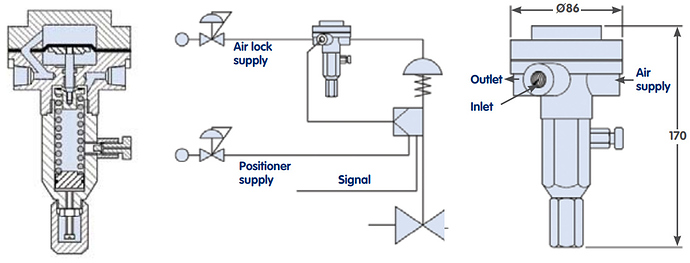

Air Lock is used when it is required to automatically hold the air pressure in diaphragm chamber of the actuator, on the same level in an event of failure of air supply. When supply pressure drops below a preset value, the Air Lock Relay locks the air pressure in the diaphragm chamber of the actuator thereby holding the inner valve in one position, till the air supply is resumed.

Cut off Setting

-

The cut off setting is adjustable and is generally set at a much higher value than required for the operation of the control valve.

-

If the actuator pressure range is 0.2-1.0 Kg/cm², the setting of this relay could be much higher than 1.0 Kg/cm² as desired for cut off.

-

Where many control loops are involved, the setting of this relay therefore needs impulse connection for cut off from the air supply header.

-

Cut off setting has been factory adjusted to the desired cut off value. Should it be required to re-adjust the cut off setting, this could be achieved either while the unit is already installed and connected to the system or separately on the test bench.

-

Inlet supply air and the outlet output gauge should be available to re-adjust the setting.

-

To adjust the cut off setting, remove cap and adjust spring adjusting screw until desired outlet cut off pressure is achieved. Please note that air lock pressure differential is approx. 0.17 Kg/cm² higher than the set cut off pressure.

-

Turning the adjusting screw clock-wise will increase the cut off setting and turning anticlockwise will reduce the cut off setting. In this relay, a built-in manual relief valve is provided if the control valve has manual hand wheel. This exhausts the air from the diaphragm chamber when the hand wheel is operated to avoid damage to the actuator diaphragm.

-

Replace cap securely after having re-adjusting the cut off setting.

Reference - Valve Solutions