Bank Tube:

-

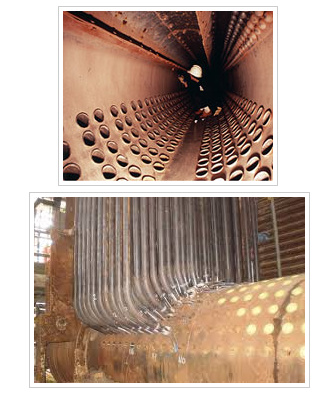

Bank tubes are provided in Bi Drum Boiler. Boiler Bank tubes have steam drum and mud drum.

-

Bank tubes are provided between these two drums.

-

It acts as a down commer and raiser between theses drums.

-

It supports the whole weight of the mud drums and down commers.

-

Any failure on these tubes Damage the near by tubes. so it must be attended immediately

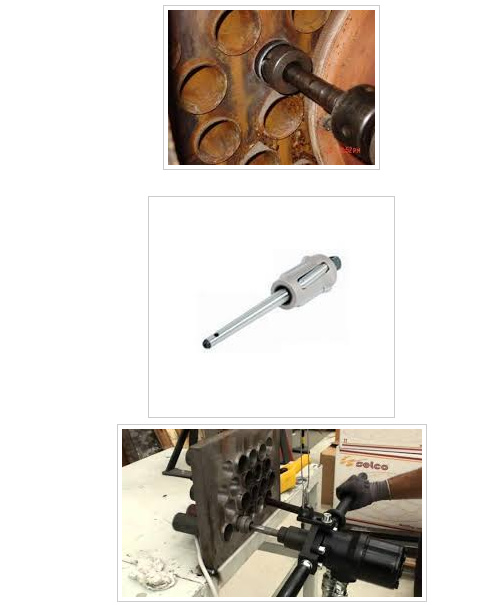

Bank tube and Drum connection

-

The bank tubes are held inside the Drum holes by expanding it with a expander. while expanding the tube expands and deform plastically and the drum being in elastic condition exerts force to hold the tube against pressure.

-

while expanding the bank tube, its thickness reduces 7 to 11 % this indicates the good joint.

-

Normally these joints are good upto pressure of 120 kg/cm2

-

sometimes bank tubes are seal welded with the drum to avoid any leakages during operation

Bank Tube Expansion:

Reason for bank tube Failure

-

The main reason for bank tube failure is due to inadequate expansion. More than 1000 bank tubes will be there and its difficult to measure the tube thinning for all the tubes after expansion. tube thinning measurement is done randomly for 200 tubes after expanding all the tubes.the requires torque is applied using expander to all the tubes and its taken for granted that all the tubes are expanded

-

Expanded joints also fail due to large number of start up and shutdown which causes thermal shock to the tubes.

-

Internal deposit leading to long term overheating Failure

-

Blockage resulting short term overheating failure

-

Errosion and Corrosion of the tube Surface

Bank Tube Leakage attending procedure

-

If bank tube failure occurs at expanded joint. This Leakage can be attended by plugging in both top and bottom drum.This is mainly due to the reason that failed tubes cannot be reached which could be between large number of tubes.

-

spool piece welding should not be done in bank tubes as this can cause failure in bank tubes

-

The expansion leakage can also attended by re expanding all the tubes but the tube thinning must be limited to 13 to 15 %. More than that the tube cause brittle and leads to failure

-

Seal welding is permitted after all the bank tubes are expanded.

Replacing all the bank tubes

There are at times all the bank tubes must be replaced due to lot of plugging. for this bottom drum must be perfectly supported and the bank tubes can be removed. and after removing the drum holes must be checked for dimension.

if dimension deviate due to steam and water corrosion it must be corrected by weld buildup. Don’t seal weld the bank tube without proper expansion