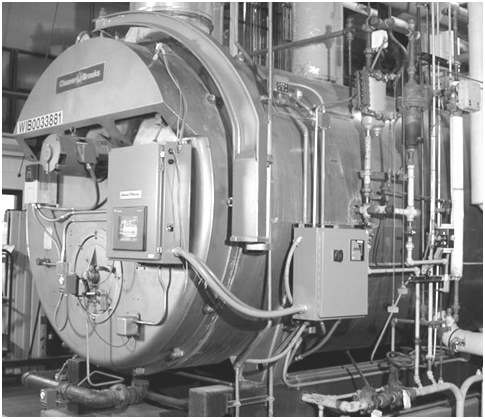

Safe Operation and Troubleshooting of CB-HAWK Boiler Management Control System

The CB-Hawk boiler management control system (’’‘Figure 1’’’) combines the functions of a flame safeguard programmer with those of operating and firing rate controls. It also monitors the fuel pressure and temperature (if required) with solid-state sensors and provides a built-in safety limit control of those functions. This system is used on most types of steam or hot water boilers, including fire-tube, industrial water-tube, and commercial water-tube. The control system is designed to operate a gas, oil, or combination burner using a single modulation motor and provides the best results when used with a fully modulating burner.

Figure 1: CB-HAWK Boiler Management Control System

The burner and control system are in the starting condition when the following conditions exist:

- Boiler water is up to the correct level, closing the low-water cutoff switch.

- The low-water light (panel) is off.

- The operating limit pressure control (steam boiler) or the operating limit temperature control (hot water boiler) and high limit pressure or temperature control are below their cutoff setting.

- All applicable limits are correct for burner operation.

- The load demand light glows.

- All entrance switches are closed and power is present at the line terminals of:

- Blower motor starter

- Air compressor motor starter (if provided)

- Oil heater relay (if provided)

- Oil pump motor starter (if provided)