A burner management system (BMS) is primarily concerned with the interlock, sequence, and timing functions required to safely put burners into service and to stop fuel and trip the boiler on the detection of potentially unsafe conditions (master fuel trip).

- BMS interlocks must be implemented with dedicated systems. They can be accomplished by hard-wired relay logic, solid-state logic, or programmable logic controllers (PLCs).

- The BMS is considered a safety instrumented system (SIS). Therefore, if PLC technology is used, it is often based on 1oo2 (one-out-of-two) or 2oo3d (two-out-of three with diagnostics) logic.

- The first one has two channels (two independent CPUs); the second has three channels (three independent CPUs, as in triple modular redundant systems).

- The criterion for selecting a certain type of SIS equipment is based on a safety integrity level (SIL) assessment that determines the degree of integrity required of the SIS based on probability and impact severity of risks.

- Master fuel trip cannot be reset; i.e. the burner light-off sequence cannot be started unless a proper purge sequence has been executed.

- The purge helps prevent accumulation of unburned fuel in the boiler after trips or failed start sequences. Furnace explosions are often related to accumulation of unburned fuel.

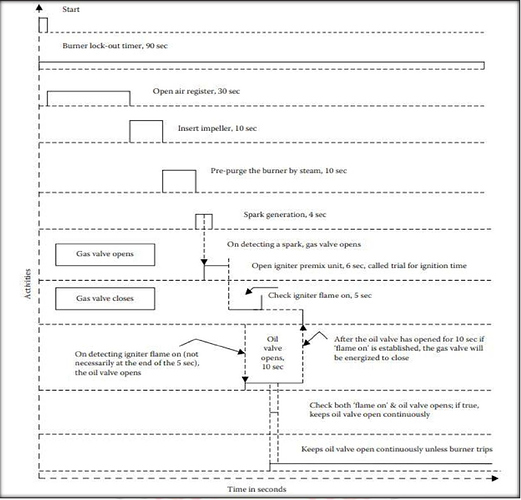

- Automatic start-up sequencing for lighting the burners and for sequencing them in and out of operation is common.

- Timing for a portion of the typical light-off sequence for a 350 MW dual-fired (oil and coal) burner with gas igniter is illustrated in the following figure.