What are the similarities and differences between PLC, DCS and SCADA systems ? Also Compare PLC, DCS and SCADA.

Compare PLC, DCS and SCADA

In the past the strength and weakness of both the automation technologies were well understood. So it was easy for engineers to select the one that suits their application, but now due to the advent of microprocessors both the technologies are merging.

The requirements which are thought to be exclusive to one technology can be found in the other one too.But still there are some things which are to be checked out before selecting the one that suits your application the best.

Now a days you cannot really tell the difference between a PLC or a DCS. Since the PLC was integrated with Analog I/O it crosses the boundary of being just digital and crosses to the realm of DCS in handling Analogs, Bus Systems, Distributed I/O and etc.

Also, since the DCS now handles logics of Digital I/O it also crossed the boundary to the realm of PLC.

As you know PLC as to its name Programmable Logic Controller. Its main purpose is to replace the relay logic controls which is “On” or “Off”. And DCS “Distributed Control Systems” its emphasis is Fast analog handling because of communications through Bus systems, networking and etc.

Summarizing all these, PLC = DCS…BUT still there are basic differences as below

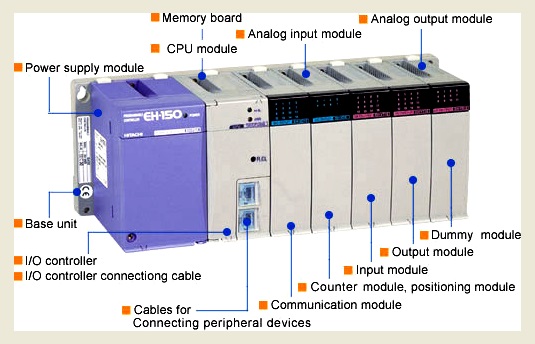

PLC is a programmable Logic controller which is used mainly for interlocking different equipments.PLC using for perticular mechine or production unit.PLC is economicaly low cost.PLC’S can handle analog and digital I/O as earliear it could handle only digital.

PLC’S are automatic controllers which is a substitute to hard wired controllers.they are extensively used for automation.PLC is for stand alone sytem.PLC is used Commonly with On\Off (Digital) Control and may be expanded with Analog I\O Modules for Analog Control and used for a control task.

Programmable Logic Controller

DCS: DISTRIBUTED CONTROL SYSTEMS: THIS SYSTEM DOES WHAT A

PLC WOULD DO, BUT THE DIFFERENCE IS THAT A DCS IS USED IN

MUCH LARGER AND COMPLEX APPLICATION E.G: POWER GENERATION,

SOME COLD ROLLING MILLS etc.

DCS is the System in which controller are distributed geographically and integrated all the control hardwares .which is connected from the various field devices .DCS having its own network, Controller and HMI etc….

Honeywell, Yokogawa, Invensys, ABB, Emerson are the leading .DCS Vendors.DCS is the System in which controller are distributed geographically and integrated all the control hardwares which is connected from the various field devices.DCS having its own network, Controller and HMI etc…

Honeywell, Yokogawa, Invensys, ABB, Emerson are the leading DCS Vendors

Distributed Control System

If taken from a narrow point of view, maybe PLC and DCS are functionally the same. However, a lot of plant technicians and engineers are not aware of the other side of the debate, namely the engineering effort and the commercial ramifications.

Of course, for huge plants with I/O’s ranging from 10,000 to 30,000 I/O points, and beyond, it is silly to even think about PLC. From my experience, a DCS is not the same with PLC in the realm of huge systems such as oil and gas plants, as the following list will show:

-

A PLC is cost-effective up to a certain I/O count, and so is the DCS. But the difference is in their starting points: the PLC is cost-effective from 0 to a few thousand I/O points; the DCS becomes cost-effective starting from a few thousand points and beyond.

-

A PLC becomes a subsystem of the DCS in rare occasions when the situation calls for it, i.e., purchase of huge package systems with engineering schedules incompatible with the DCS schedule (I/O lists cannot be submitted on time before the DCS hardware freeze date). Note that this package system is a process system using continuous control, not discrete. Based on this, a PLC can never be larger than a DCS in terms of I/O count.

-

In large plants the DCS is king because most owners want a single source of hardware support and service, and this mentality naturally denies the PLC a foothold. Package vendors are no longer required to provide PLC for their system. Everything is connected to the DCS.

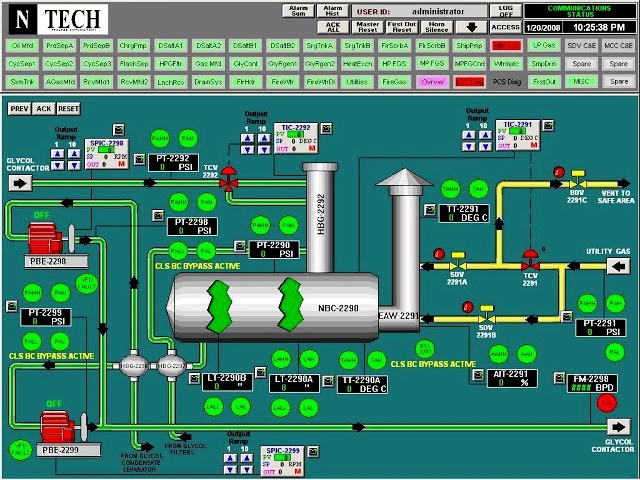

SCADA: AS ALREADY EXPLAINED, IT NOTHING BUT A SOFTWARE USED

TO GATHER DATA FROM THE FIELDS INSTRUMENTS WITH THE HELP OF

YOUR DCS OR PLC DEPENDING ON THE APPLICATION VIA THE SERVER

AND MAKING IT AVAILABLE IN AN ANIMATED FORM. THIS IS

USUALLY FOUND IN YOUR CONTROL ROOMS AND DEVELOPMENT ROOM

SCADA

SCADA is the Software tool in which you can able to view/Monitor/Control your Process Variable data and Graphical representation of your plant etc…It’s an operator front end display Example of few SCADA S/W is Wonderware, IFix, RS View, WinCC etc

SCADA is Supervisory Control and Data Aquisition which is used to control and Monitor small number of Equipments in a field.SCADA systems are typically used to perform data collection and control at the supervisory level.

Some systems are called SCADA despite only performing data acquisition and not control.The supervisory control system is a system that is placed on top of a real-time control system to control a process that is external to the

SCADA system (i.e. a computer, by itself, is not a SCADA system even though it controls its own power consumption and cooling).

This implies that the system is not critical to control the process in real time, as there is a separate or integrated real-time automated control system that can respond quickly enough to compensate for process changes within the time constants of the process

SCADA is the Software tool in which you can able to

view/Monitor/Control your Process Variable data and

Graphical representation of your plant etc…

It’s an operator front end display

Example of few SCADA S/W is Wonderware, IFix, RS View,

WinCC etc

IN SHORT!

PLC :

-

in manufacturing processes(for production of things)

-

for simple batch control

-

intensive logic controls

-

can handle a no. of I/O s at a time

-

downtime => lost production

-

usually,no need of redundancy

-

fast logic scan(=reading I/Ps executing instructions and providing O/Ps)

-

compact

-

easily customised

-

for smaller applications

DCS :

-

in process control (for production of stuff)

-

for complex batch control

-

advanced analog loop controls

-

downtime=>lost production+damage to process equipment+ may lead to dangerous conditions

-

so Redundancy must

-

large in size

-

cant be easily customised

-

for larger applications and plant-wide

In detail

What are you manufacturing??

PLC:for simple batch control i.e.,manufacturing a batch of goods(things)

Eg.,in bottling plants

DCS:for complex batch process i.e.,producing a product by transmission from raw materials(producing stuff)

Eg.,in oil refining plants,in steel making

Specific to type of control

PLC: very logic control intensive.Can handle a no. of digital and analog I/O’s at a time.

DCS: Regulatory/Analog loop control .It also provides ratio/cascade/model-predictive /feed forward control

Effect of downtime

What is downtime?

It is the time that the process takes to come to normal operation after a catastrophic failure.

PLC: Downtime results in only lost production and does not typically damage the process conditions or equipment.

For eg.,if there is some problem in the manufacturing process of a bottling plant, even if the process is stopped for a while, resuming the process back to its normal operation is simple and not time tacking. providing redundancy will be costlier than handling the downtime expenses so generally redundancy is not provided by this.

DCS: Downtime results not only in lost production but also leads to dangerous conditions or damages the process line and resuming the process is expensive and difficult too.

For eg.,In steel making process if the process stops abruptly and the pipelines with process fluid contents may freeze and damage the pipelines this would lead to more expenses.

Degree of customisation

PLC:It delivers a tool-kit of functions and building blocks that can be easily customized .So it can be used for varied applications by programming it according to the application.

DCS: Its highest priority is high reliability so standard functions are baked in to provide a complete solution to a particular application. So it can’t accept many custom modifications .

Up-front cost

PLC: in $$.

DCS: in $$$$ ;However its superior to PLC in operation and proprietary in general.

Size

PLC: compact

DCS: large

Replacement

PLC: replaced the conventional relays

DCS: replaced the pneumatic & single loop controllers

DCS is Distributed Control Systems which is used to control very big plants by using simple GUI screens.PLCs are interfaced with DCS for interlocking.