The process of cleaning the tubes, condenser is very important at Power stations, this system removes sediment and plankton, which are adhesive pipes intensive internal, and not cleaning those pipes result in major problems is the lack of efficiency of the process intensification of steam into water, thus the lack of sustaining pressure VACUUM within the condenser.

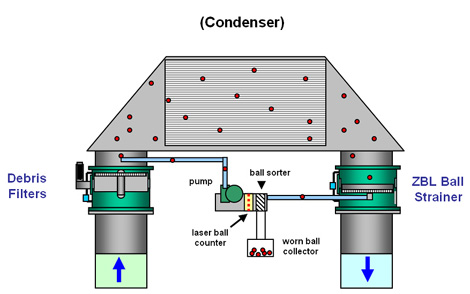

Rubber sponge balls are injected into circulating water (CW) flow at the inlet of a heat exchanger. The sponge balls are circulated through the heat exchanger tubes, where they mechanically remove fouling debris and scale that builds up on the tube surfaces. Sponge balls are then collected at the condenser outlet by a ball strainer and re-injected at the inlet to continuously maintain the cleaning process.

so many advantages are provided from using this on-load system:

1- Prevents and removes fouling and scale build-up on condenser tubes

2- Ensures optimal heat transfer to maintain design steam side pressure

3- Lowers fuel consumption

4- Raises plant output to original design specifications

5- Eliminates regular shutdowns for costly manual tube cleanings

6- Reduces chlorination usage and expense

7- Extends condenser life