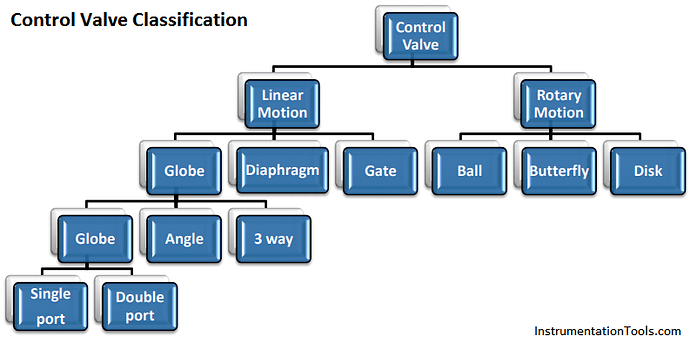

Different Types of control valves

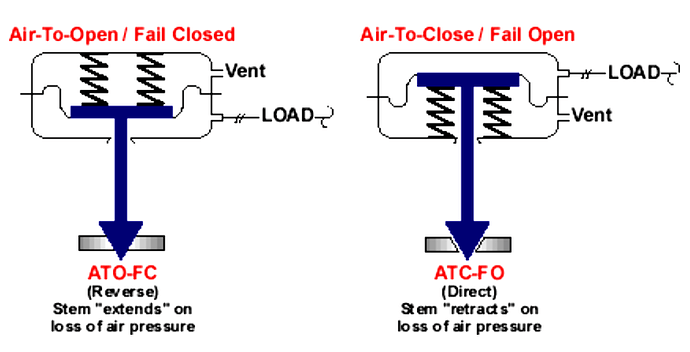

ATO/ATC (Air to open/close valves)

Air to open valves are normally held closed by the spring and require air pressure (a control signal) to open them - they open progressively as the air pressure increases.

Air to close valves are valves which are held open by the valve spring and require air pressure to move them towards the closed position.

The reason for the two types of valves is to allow failsafe operation. In the event of a plant instrument air failure it is important that all control valves fail in a safe position (e.g. an exothermic reactor’s feed valves (or, perhaps, just one of the valves) should fail closed (air to open) and its coolant system valves fail open (air to close)).

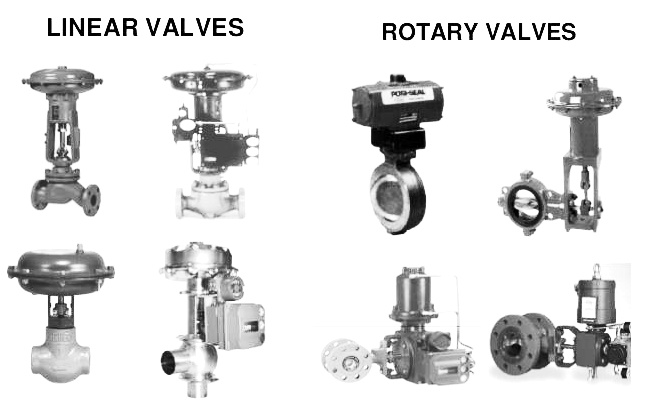

Linear/Rotary Valve

Linear valves, also known as multi-turn valves, have a sliding-stem design that pushes a closure element into an open or closed position by moving plug in a straight line to start, stop, or throttle the flow…

Rotary valve use a closure element that rotates a disc or ellipse about an angular or circular shaft extending across the diameter of an orifice usually through a quarter-turn or 90° range, to block the flow.

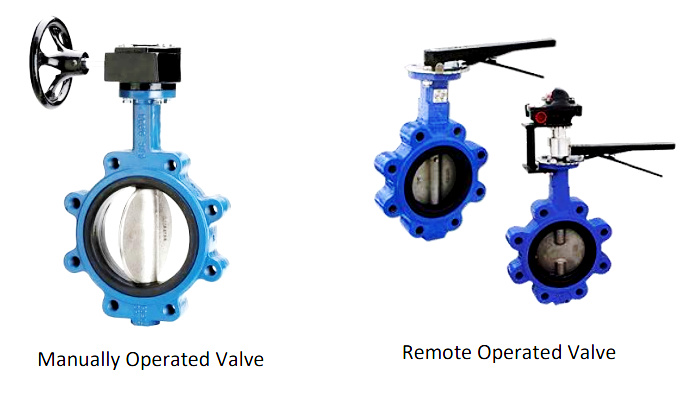

Manually operated/Remote operated

Closure of the valve can be initiated only from a point local to the valve itself is known as manually operated valve.

Closure of the valve can be initiated from a point remote from the valve itself is known as the remotely operated valve.

Based on plug shapes

Following are the types of valve based on the plug shapes.

- Gate Valves

- Globe Valves

- Plug Valves

- Ball Valves

- Butterfly Valves

- Needle Valves

- Check Valves

- Pressure Relief Valves

- Diaphragm Valves

Based on actuators

Following are the types of valves based on the types of actuators.

Manual: A manual actuator employs levers, gears, or wheels to move the valve stem. Manual actuators are powered by hand.

Pneumatic: Air (or other gas) pressure is the power source for pneumatic valve actuators. Air pressure acts on a piston or bellows diaphragm creating linear force on a valve stem.

Hydraulic: Hydraulic actuators convert fluid pressure into motion. Fluid pressure acting on a piston provides linear thrust for gate or globe valves.

Electric: The electric actuator uses an electric motor to provide torque to operate a valve.

Also Check below article