This attack by corrosion occurs especially on the inner walls and internal parts of control valves and is therefore often influential in the durability of a component or for the entire valve. If one examines this corrosion process more closely, one finds that insoluble corrosion products forming an oxide layer develop on the material surface. This layer causes a separation between the attacking fluid and the material. This normally very thin layer is designated as the "passivation layer“ which prevents or at least delays a further corrosion.

For this reason, high quality austenitic steels are usually treated at first in a pickling plant before any further fabrication. In this passivation process old oxide layers along with scaling and iron dust are removed and a new, precisely controlled passivation layer is formed. It is obvious that this layer must not show cracks and must not be damaged, otherwise the corrosion attack will continue.

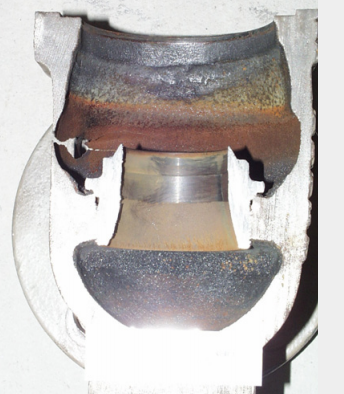

Figure - Corrosion by a too high velocity of flow.

High flow velocities in the interior of the valve, fluids containing hard particles and cavitating fluids, however, permanently destroy this passivation layer, resulting in a gradually uniform surface corrosion of all parts. This finally limits the durability of certain parts or even the entire control valve.

Because of the special importance of the valve trim with regard to characteristics and rangeability, a uniform material removal at the plug or seat ring is, of course, considerably more undesirable than a material loss of the body walls. This is also the major reason why for these trim parts a higher corrosion resistance and a better resistance against wear & tear is always required…

Ref - samson