The flow regulation in a valve is accomplished by the varying resistance as the valve is stroked, i.e. its effective cross sectional area is changed.

As the fluid moves from the piping into the smaller diameter orifice of the valve, its velocity increases to enable mass flow through the valve.

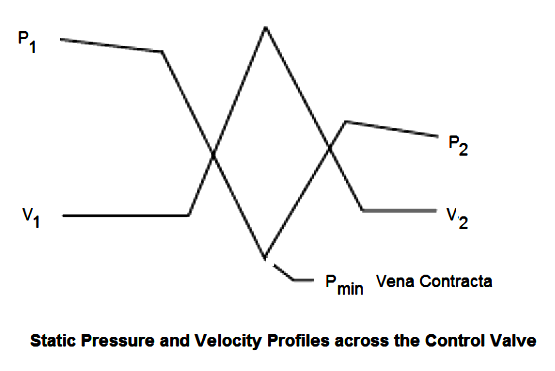

The energy needed to increase the velocity comes at the expense of the pressure, so the point of highest velocity is also the point of lowest pressure (smallest cross section).

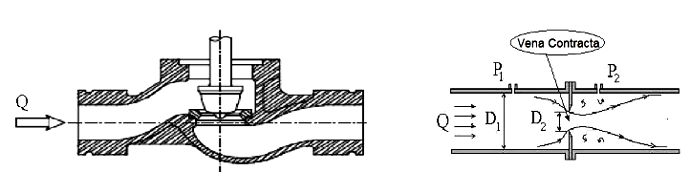

The point where the pressure is at the lowest is called “vena contracta” .

Control Valve Fundamentals

To display the general behavior of flow through a control valve, the valve is simplified to an orifice in a pipeline as shown in the figure below:

As the liquid passes the point of greatest restriction (vena contracta); its velocity reaches a maximum and its pressure falls to a minimum.

Hence we would expect the highest velocity at the internal to the valve than on upstream and downstream. Beyond the vena contracta, the fluid’s velocity will decrease as the diameter of piping increases.

This allows for some pressure recovery as the energy that was imparted as velocity is now partially converted back into pressure (refer pressure-velocity profile below).

It is important to understand how the pressure-velocity conditions change as the fluid passes

through the restriction.

This is best described by the continuity equation:

V1 * A1 = V2 * A2

Where:

• V = mean velocity and

• A = flow area.

• Subscript 1 refers to upstream conditions

• Subscript 2 refer to downstream conditions

The equation shows that the velocity and hence the pressure can be changed by adjusting

the valve opening (area). With this introduction, we will jump straight to control valve basics

and the readers interested in further reading should read the basic principles of hydraulics.