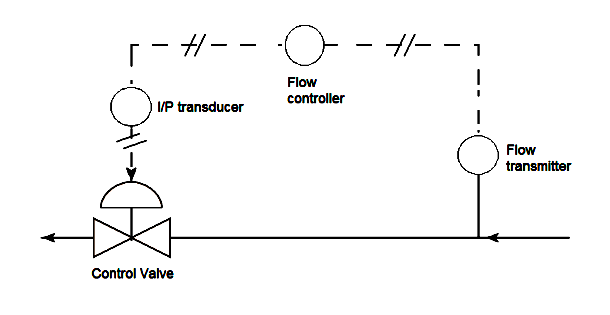

A control loop consists of a sensing element, a controller ( Distributed Control System ) and the final control element - the valve and its actuator.

Control Valve Operation using Distributed Control System (DCS)

The sensing element transmits a signal to a single controller or a distributed control system (DCS). The controller compares the signal with the setpoint, and then makes any needed corrections by sending a signal to the control valve.

The correction is measured and verified by the sensing element, completing the loop. The I/P transducer changes an electronic signal into one that is pneumatic.

A control valve should react instantaneously to any change in the signal. To be effective, a valve should: operate over a wide range of flows (have a wide rangeability); accurately respond to any signal across its operating range; exhibit little dead time or hysteresis; react to incremental adjustments from the controller (resolution); and respond with the required speed (stroking speed).

A fast response may not be suitable for all applications. For example, a quick or sudden reduction in the bore of a valve in a pipeline may be harmful, causing a shock wave. A valve’s ability to control flow depends upon the quality of its actuator.

A positioner may be added to obtain a more-precise response and tighter control. The quality of any control device can be quantified in terms of its gain, time constant and dead-time lag. Of these, the gain is the most important for a control valve.

Gain is the ratio of the percentage change in a process variable to the percentage change of the valve travel. Gain depends upon the valve characteristics and process conditions.