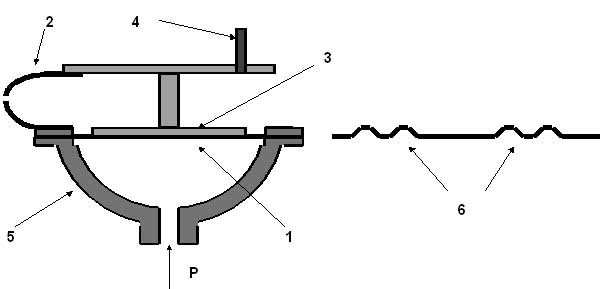

Another type of pressure gauge, which utilises elastic-element properties, is a diaphragm pressure gauge. These gages are used when very small pressures (from 125 Pa to 25 kPa) are to be sensed. Fig. shows a sensitive element for this type of pressure gauge.

A flexible disc 1 made of trumpet brass, or phosphor bronze, or beryllium copper, or titanium, or tantalum, etc., is used to convert the measuring pressure to the deflection of the diaphragm. Deflection vs pressure characteristic should be close to linear as much as possible. In reality for a flat diaphragm this characteristic is non-linear. So, flat membranes are not used as sensitive elements. To linearise this relationship special diaphragms with concentric corrugations 6 are designed. Linearisation of a static characteristic of the membrane can be achieved by using a flat spring 2, which is connected, to the diaphragm through the mechanism 3. The movement of the mechanism 3 is transmitted by the link 4 to a pointer of the gauge.

The measuring pressure is supplied to the pressure chamber 5 and causes the diaphragm to move upwards until the force developed by this pressure on the diaphragm is balanced by the force acted from the spring. To increase the sensitivity of this type of pressure gauge, we may increase the diameter of the diaphragm, to lengthen the spring, to change the material of the diaphragm and the spring to more elastic, to increase the depth and the number of corrugations of the diaphragm.

When pressure is applied to both sides of the membrane, then the resultant reading is proportional to the differential pressure. The space above the diaphragm is connected to atmosphere, so the diaphragm separates a measured media from the environment. In other words, it serves as a fluid or gas barrier or as a seal assembly, thus preventing contact of corrosive and aggressive fluids with pressure elements.

Accuracy of diaphragm pressure gages varies from ±1.0 to ±1.5% of the span.