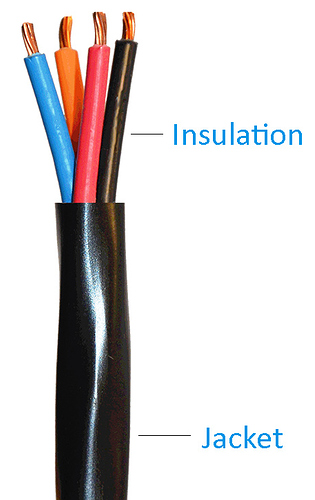

Differences between Cable Jackets & Insulations

A jacket is an outer sheath that protects the wire or cable core from mechanical, moisture and chemical issues. Jackets help with flame resistance, protect against sunlight and facilitate installation. Jackets come in a variety of types and styles and are mainly plastic or rubber based.

Insulation is a coating that is extruded or taped onto bare wire to separate conductors from each other electrically and physically. There are a variety of insulation types for different applications.

Types of Jackets & Insulations:

Thermoplastic

Thermoplastics are the primary insulation and jacket used in wire and cable. A Thermoplastic is a material that softens when heated and becomes firm when cooled. Thermoplastics come in a variety of different types each with its own set of characteristics.

Types: PVC, Fluoropolymers, Polyolefins, TPE

Thermoset

Thermoset plastics are a group of compounds that are hardened or set by the application called cross-linking. Cross-linking is accomplished by a chemical process, vulcanization (heat & pressure) or irradiation.

Types: CPE, XLPE, EPR, Silicone Rubber

Fiber

Fiber jackets are commonly used in high temperature applications due to their excellent heat resistance. Fiber jackets are also flame resistant and can be used as overbraids for silcone rubber insulation.