Pitot tube

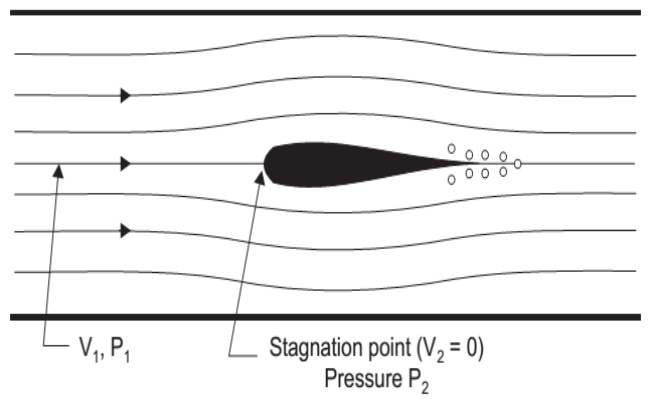

Consider Fig. which shows flow around a solid body. When a solid body is held centrally and stationary in a pipeline with a fluid streaming down, due to the presence of the body, the fluid while approaching the object starts losing its velocity till directly in front of the body, where the velocity is zero.

This point is known as the stagnation point.

As the kinetic head is lost by the fluid, it gains a static head.

By measuring the difference of pressure between that at normal flow line and that at the stagnation point, the velocity is found out.

This principle is used in pitot tube sensors.

Construction:

-

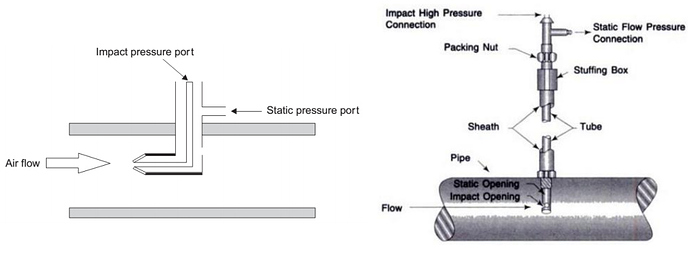

The simplest Pitot tube consists of a tube with an impact opening of 3.125 mm to 6.35 mm diameter pointing towards the approaching fluid.

-

This measures the stagnation pressure. An ordinary upstream tap can be used for measuring the line pressure.

-

A common industrial type of pitot tube consists of a cylindrical probe inserted into the air stream, as shown in Fig. 2.

-

Fluid flow velocity at the upstream face of the probe is reduced substantially to zero.

-

Velocity head is converted to impact pressure, which is sensed through a small hole in the upstream face of the probe.

Working:

-

A corresponding small hole in the side of the probe senses static pressure.

-

A pressure instrument measures the differential pressure, which is proportional to the square of the stream velocity in the vicinity of the impact pressure sensing hole.

-

The total pressure developed at the point where the flow is stagnated is assumed to occur at the tip of a pitot tube or at a specific point on a bluff body immersed in the stream.

-

The pitot tube causes practically no pressure loss in the flow stream. It is normally installed through a nipple in the side of the pipe.

-

It is frequently installed through an isolation valve, so that it can be moved back and forth across the stream to establish the profile of flow velocity.

Advantages:

- No pressure loss.

- It is relatively simple.

- It is readily adapted for flow measurements made in very large pipes or ducts.

Disadvantages:

- Poor accuracy.

- Not suitable for dirty or sticky fluids and fluids containing solid particles.

- Sensitive to upstream disturbances.

Applications

- Pitot tube is employed in a variety of flow measurement applications like air speed in racing cars and Air Force fighter jets. In industries, pitot tubes are invariably put into use for measurement of

- Air flow in pipes, ducts, and stacks, and

- Liquid flow in pipes, weirs, and open channels