When fluid or gas flows through a taper tube containing a float, a pressure difference is created between upper and lower side of the float.

The float moves upwards by a force obtained by multiplying the pressure differential by the maximum cross sectional area of the float.

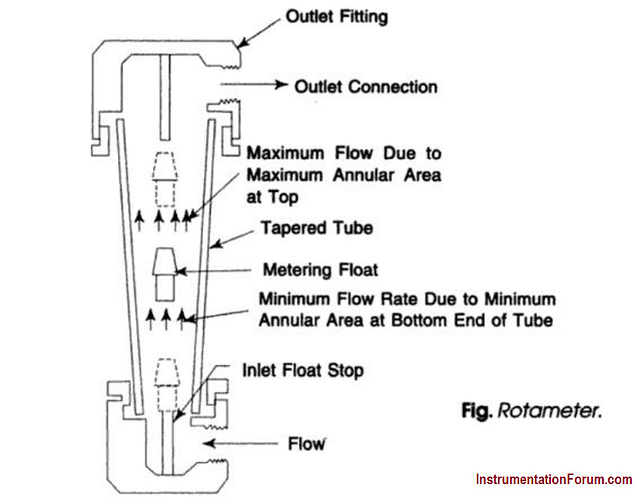

Variable area meter : Rotameter

Due to taper tube, as the float moves upwards, the fluid passing area increases because of which the differential pressure decreases. Upward movement of float stops when the differential pressure dynamically balances the dead load.

Tapering of metering tube is so designed that the vertical movement of the float becomes linearly proportional to the rate of flow and the scale is provided to read the position of the float, thus it gives flow rate indication.

Based on Bernoulli’s theorem, the principle mentioned above can be theoretically expressed as follows.

Q = K. A. √(gh)

Where:

Q = volumetric flow rate, e.g., gallons per minute • k = a constant

• A = annular area between the float and the tube wall • g = force of gravity

• h = pressure drop (head) across the float

Construction:

-

A rotameter consists of a tapered tube, typically made of glass with a ‘float’.

-

Float is made of anodized aluminum or a ceramic and it moves freely inside the glass tube.

-

Floats will be pushed up by the drag force of the flow and pulled down by gravity.

-

The drag force for a given fluid and float cross section is a function of flow speed squared only.

-

A higher volumetric flow rate through a given area increases flow speed and drag force, so the float will be pushed upwards.

-

However, as the inside of the rotameter is cone shaped (widens), the area around the float through which the medium flows increases, the flow speed and drag force decrease until there is mechanical equilibrium with the float’s weight.

Working:

-

The position of float inside the glass tube is measured using appropriate scale or tube itself have scale printed on it. This height of the float can be calibrated in terms of the flow rate.

-

Floats are made in many different shapes, with spheres and ellipsoids being the most common.

-

The float may be diagonally grooved and partially colored so that it rotates axially as the fluid passes. This shows if the float is stuck since it will only rotate if it is free.

-

Readings are usually taken at the top of the widest part of the float; the center for an ellipsoid, or the top for a cylinder. Some manufacturers use a different standard.

-

The “float” must not float in the fluid: it has to have a higher density than the fluid, otherwise it will float to the top even if there is no flow.

-

The mechanical nature of the measuring principle provides a flow measurement device that does not require any electrical power.

-

If the tube is made of metal, the float position is transferred to an external indicator via a magnetic coupling. This capability has considerably expanded the range of applications for the variable area flowmeter, since the measurement can observed remotely from the process or used for automatic control.

Advantages:

- Low cost

- Simplicity

- Low pressure drop

- Quite wide rangeability

- Linear output

Disadvantages:

- Vertical mounting position

- Constant pressure drop

- Affected by density, temperature and viscosity changes

- Solids damage metering edge, otherwise slight contamination allowed

- Affected by pulsation and vibration

- Expensive when exotic materials are required