The operation of many industrial processes involve inherent risks due to the presence of dangerous material like gases and chemicals. Safety Instrumented Systems SIS are specifically designed to protect personnel, equipment and the environment by reducing the likelihood (frequency) or the impact severity of an identified emergency event.

Fundamentals of Safety Instrumented Systems SIS

Explosions and fires account for millions of dollars of losses in the chemical or oil and gas industries each year. Since a great potential for loss exists, it is common to employ Safety Instrumented Systems SIS to provide safe isolation of flammable or potentially toxic material in the event of a fire or accidental release of fluids.

This online training tutorial will explain the basic concepts, definitions and commonly used terms in Safety Instrumented Systems SIS and provide a basic understanding of related concepts.

Basics of Safety and Layers of Protection

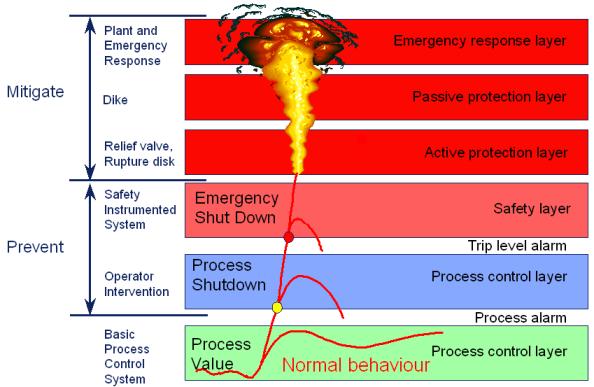

Safety is provided by layers of protection. These layers start with safe and effective process control, extend to manual and automatic prevention layers, and continue with layers to mitigate the consequences of an event.

The first layer is the Basic Process Control System BPCS. The control system itself provides significant safety through proper design of process control.

The next layer of protection is also provided by the control system and the system operators. Automated shutdown sequences in the process control system combined with operator intervention to shut down the process are the next layer of safety.

The third layer is the Safety Instrumented System SIS. It is a safety system independent of the process control system. It has separate sensors, valves and logic system. No process control is performed in this system, its only role is safety.

These layers are designed to prevent a safety related event. If a safety related event occurs there are additional layers designed to mitigate the impact of the event.

The fourth layer is an active protection layer. This layer may have valves or rupture disks designed to provide a relief point that prevents a rupture, large spill or other uncontrolled release that can cause an explosion or fire.

The fifth layer is a passive protection layer. It may consist of a dike or other passive barrier that serves to contain a fire or channel the energy of an explosion in a direction that minimizes the spread of damage.

The final layer is plant and emergency response. If a large safety event occurs this layer responds in a way that minimizes ongoing damage, injury or loss of life. It may include evacuation plans, fire fighting, etc.

Overall safety is determined by how these layers work together.