Globe Control Valve

Control valves are used to control such as pressure, flow, level, and temperature by fully or partially opening or closing in response to signal received from controllers that compare a “Setpoint” to a “Process Variable” whose value is provided by the sensors that monitor changes in such conditions.

A globe valve is a type of valve used for regulating flow in a pipeline, consisting of a movable disk-type element and a stationary ring seat in a generally spherical body.

Globe valve is the most commonly used control valve in industries. Globe valves are available in different sizes. Globe valve is used on water and steam line both. Globe Valve is used where the pressure is high.

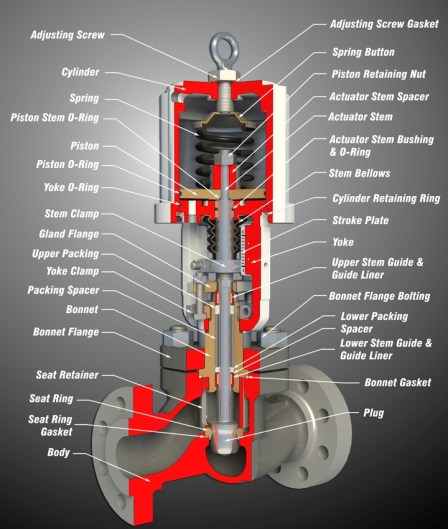

Control Valve has 2 parts.

- Actuator.

- Body.

Parts of actuator

-

Diaphragm

-

O- Ring

-

Spring

-

Wheel

The actuator is connected from the body through a coupler.

Globe Control Valve

Parts of Body

-

Plug

-

Plug stem (Spindle).

-

Balancing Ring

-

Seat

-

Cage

-

Valve position indicator.

-

Gland

-

Chuck- Nut

-

Bonnet

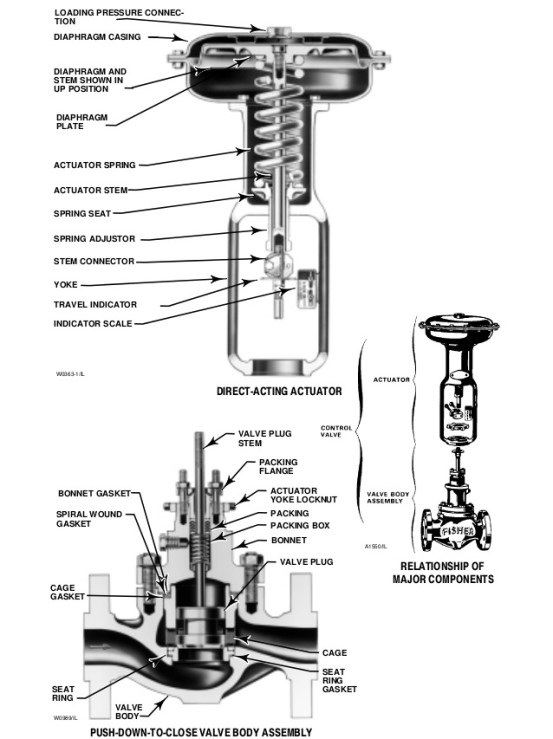

Work of different Parts of a Control Valve

Diaphragm:

The diaphragm is the most important part of a control valve. Spring remains on the diaphragm. Air firstly come on diaphragm then applied to spring. If the Diaphragm is damaged control valve does not work. The diaphragm is damaged due to access air applied to the control valve.

O- Ring

O- Ring is used to prevent air leakage.

Spring:

Spring is used to provide movement to a control valve. On apply air, spring is compressed and the control valve is operated.

Wheel:

The wheel is used for manual or auto operation of a control valve.

Coupling:

Coupling is used to connect the actuator to the body of a control valve.

Plug:

The plug is the most important part of a control valve body. Seat remains in the plug. The lower smooth part of the plug is known as the seat.

Plug Stem:

Plug stem is also known as a spindle. Plug stem is connected by the coupler to the actuator through this plug stem.

Seat:

The seat is the important part of a control valve body. When the control valve is fully closed it is Used to prevent the leakage. It means when the seat is damaged control valve will leakage on full closed.

Balancing Ring:

Balancing Ring is made up of Teflon or metal (Graphite), depending on the class of Control Valve. Balancing Ring is also used to Prevent leakage from control valve body.

Bonnet :

Bonnet is the Outer cover Of a Control Valve Body.

Globe valves are of 2 types .

- Air to open or normally closed.

- Air to close or normally open.

Air to open control valve is a valve which remains in closed position in absence of air. On applying air it is operated and starts opening. It is also called Normally Closed Valve.

Air to close control valve is a valve which remains in open position in absence of air. On applying air it is operated and starts closing. It is also called Normally open Valve.

How a Control Valve Works?

Firstly air is applied on Diaphragm then

Air Goes to Spring, Spring is compressed on applying air and control valve is operated.

Role of Wheel in a Control Valve

The wheel is used to operate a control valve manually. In some valves, the neutral position is given. In the neutral position control valve is operated through the air.

In other position, different from neutral position control valve is operated through the wheel manually. In some control valves, this wheel is not given.

Control Valve with the wheel is called the control valve with manual function.

In the control valves in which neutral position is not given if the wheel is moving freely control valve is in auto mode it will be operated through air signal.

if the wheel is not moving freely control valve is in manual mode, It will be operated through wheel operation and in this case air supply is off.