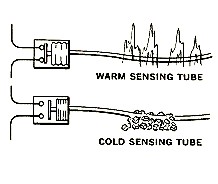

Switch contacts are connected by linkage to a flexible metal bellows which has a small tube called a capillary tube connected to it. The length of the tube is determined by the application for which it is to be used. This tube is usually filled with a substance such as freon gas of the type used in refrigerators.

The tube is crimped and sealed at one end, the other end opening into the sealed bellows. When a portion of the tube is exposed to heat, the refrigerant inside will expand, causing the bellows at the other end to move and to open or close the switch depending upon the design and application of the thermostat. As the tube is cooled, the refrigerant contracts, causing the bellows to contract, and again this reverse movement initiates switch action.

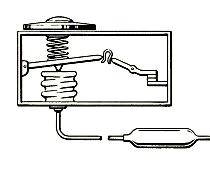

Here’s how a basic capillary tubethermostat works. The tube and charge of gas, which is designed to work at a particular temperature range depending upon application, is attached to a set of switch contacts. This one is designed for use in a refrigerator. When the temperature be comes warmer, the bellows expands and closes the contacts, starting the compressor. When the temperature becomes colder, the bellows contracts a.nd opens the contacts.

A thermostat as simple as the one above has two shortcomings: It doesn’t allow for any means of control, and the contacts don’t snap open quickly enough to eliminate arcing.

The thermostat above has a counterforce to the bellows action, in the form of a spring, which is adjusted by the setting of the dial knob. The toggle spring now imparts a snap action to the contacts. This is basically how the majority of these thermostats operate on modern refrigerators. Courtesy Whirlpool Corp.

Adjusting The Rate Of Expansion And Contraction

The rate of expansion and contraction may be adjustable by a spring load upon the bellows or switch linkage. For instance, when you set your oven thermostat to 300 degrees, what you’re actually doing is setting up a precalculated spring load against the bellows of your oven’s thermostat.

As the oven heats, the pressure within the bellows builds up to a point where it finally overcomes the spring load, which should occur at approximately 300 degrees. This movement opens the contacts, and the heating element within the oven is turned off.

Again, as the oven cools below 300 degrees, the bellows contracts and the switch is closed, completing the circuit to the heating element. It continues to cycle in this manner until the thermostat is turned off or set to a different temperature. Thermostats such as these are durable and extremely accurate.