Inductive and Capacitive sensors use a high frequency oscillator that creates a field in the close surroundings of the sensing surface. The presence of a metallic object (inductive) or any material (capacitive) in the operating area causes a change of the oscillation amplitude.

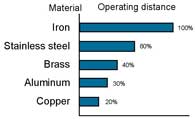

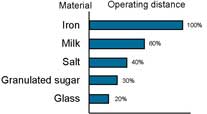

The rise or fall of such oscillation is identified by a threshold circuit that changes the output state of the sensor. The operating distance of the sensor depends on the actuator’s shape and size and is strictly linked to the nature of the material (Fig. 1 & Fig. 2).

A trimming screw placed on the capacitive sensors allows regulation of the operating distance. This sensitivity regulation is useful in applications, such as detection of full containers and non-detection of empty containers.

Fig.1 Sensitivity when different metals are present (inductive).

![]()

Fig.2 Sensitivity when different metals are present (capacitive).

![]()

Photoelectric

Diffused-reflective (direct reflection) - uses the light reflected directly off the object for detection. In the use of these photocells, it is important to bear in mind the color and the reflectiveness of an object can affect the sensing distance. The operating distance in the technical data is related to matte white paper. Select diffused-reflective models have a trimmer for sensitivity adjustment.

Retro-reflective (reflection with reflector) - an object is detected when it interrupts the light beam between the sensor and reflector. These photocells allow longer sensing distances, as the rays emitted are almost totally reflected towards the receiver.

Through Beam - detects an object when it interrupts the light beam between the emitter and receiver. These photocells allow for the longest distances. Influence of different material on the operating distance of diffused-reflective sensors only

Influence of different material on the operating distance of diffused-reflective sensors only