When it has been decided that instrument is required to be installed for specific service, the next job is to select to most suitable instrument type.

The following are several factors that should be considered when choosing the right instrument:

Process condition and properties

The fluid phase is the first thing to concern: gas, liquid or two-phase . Some type instruments are only suitable for particular phase while some others works properly on all kind of fluid phase.

Selected instrument shall also withstand to pressure and tempeture operating of proces fluid.

The process condition of fluid whether clean, dirty or containing slurries will also limit the instrument type selection. In addtion, corrosiveness of fluid will determine the selection of its material.

Range of process variable to be measured shall be specified. The wide range will require instrument type which has high turn down ratio, it means some type of instrument which has low turn down ratio will not be applicable.

Some instrument type is not designed for high viscosity services. Turbine meter will not work properly in high viscosity liqud, the float of magnetic level gauge might stuck and not floating to follow the level interface change.

Other properties such as reynold number shall be satisfied to particular number for some type of flow instrumentation.

Performance requirements

Each Instrument has static and dynamic characteristics . Accuracy, repeatability and linearity are some of characteristic that mostly being concern. The selection of instrument based on performance requirement is depend on the purpose of the instrument whether is it for process monitor, process control, safety, inventory measurment or custody transfer metering.

Environmental condition

The location of instrument shall be identified wheter it is classified as hazardous area or not. If so, the design of instrument shall be properly chosen to certified device which comply with the intented area.

Ingress protection of instrument enclosure shall be specified to suit the enviroment whether it is located in dry, dusted, offshore installation, etc.

The ambient temperature shall also be considered because it will affect some parts such as electronic parts, elastic material such as seal, packing.

For harsh environment such as extreme temperature, the use of additional instrument enclosure which is equipped with heater shall be taken into account.

Installation

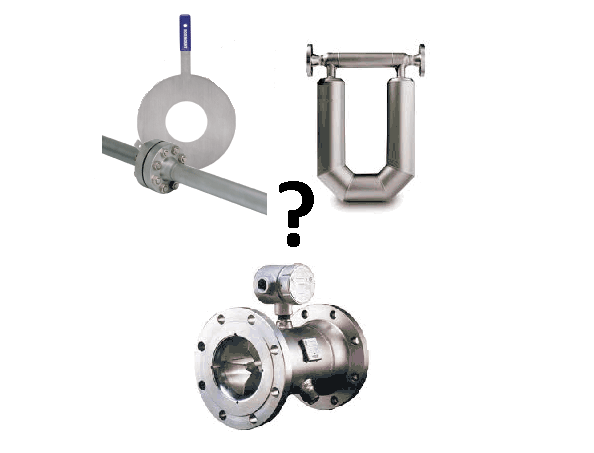

Space usually becomes an issue especially in offshore platform. For exampel, the issue in flow measurment is that some type of instrument requires straight run .

In other example, installation of level instrument which measuring low elevation sometime becamo an issue when its bottom might contact with the structure surface.

Maintenance

There are several factors which will impact during maintenance process :

-

Requirement of process shutdown

-

The capability of instrument to be calibrated in bench or vendor workhop

-

Ease of dismantling

-

Special tools/equipment requirement

-

Requirement of specialist personnel

-

Availability of spart part

Cost

Besides initial cost of the goods price and its installation, maintenance cost should be thoroughly evaluated in all aspects which comprise of spare part price, thrid party service and downtime/production loss if the instrument required by plant operation.

For flow measurement, DP type flow meter creates process cost (pressure loss). If the pressure outlet of the system is lower than the requirement, it needs more compression or pumping system which will significantly increase the budget.