How to check leakages of Air pre-heater (Turbine)

What is leakage ?

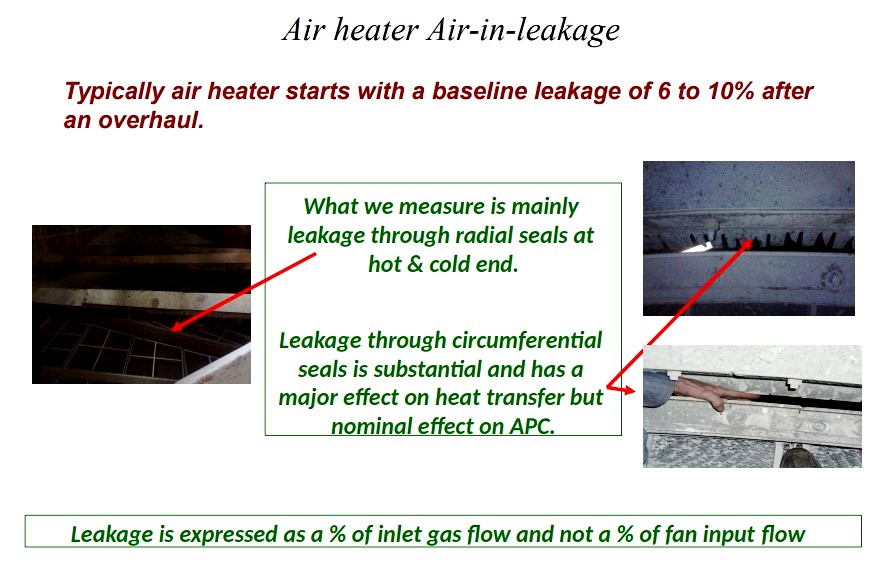

The leakage of the high pressure air to the lowpressure flue gas due to the Differential Pressure, increased seal clearances in hot condition, seal erosion / improper seal settings.

➢ Direct – flow of air through gaps between rotating and fixed structure;

Leakage ≈ gap area x (density x ∆P)1/2;

➢ Entrained – volume of air in porous elements carried via rotation from air side to gas side

Leakage whether direct or entrained has no effect on the heat transfer efficiency of air heater; the gas temperature leaving air heater decreases by mixing of the cooler air with the flue gas.

Factors affecting performance include

- Operating excess air levels & PA/SA ratio

- Inlet air / gas temperature

- Coal moisture

- Air ingress

- levels Soot

- blowing

- No. of mills in service & PA Header Pressure

- Upstream ash evacuation

Maintenance practices - Condition of heating elements, seals / seal setting, sector plates / axial seal plates, diaphragm plates, casing / enclosure, insulation

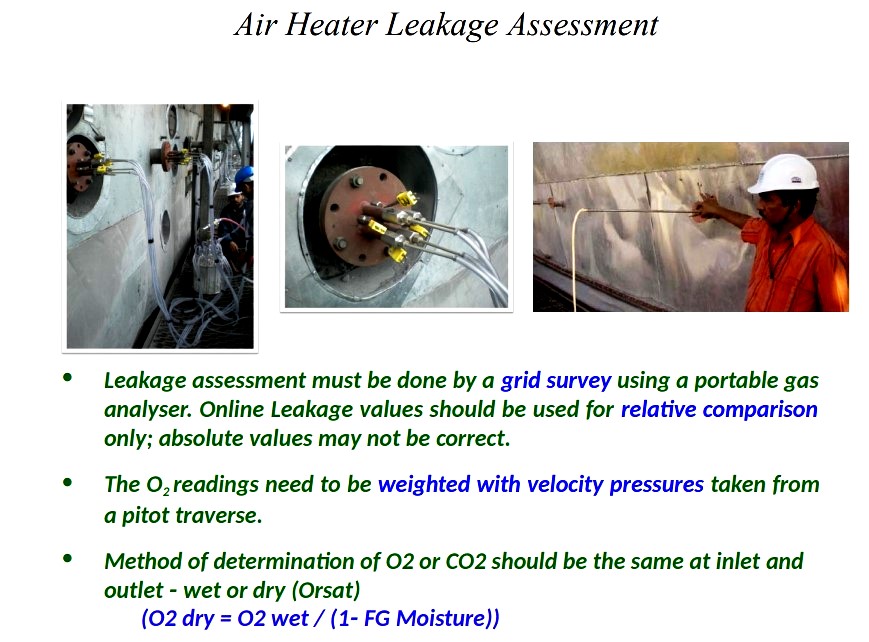

AH Tests –Measurements

• Gas analysis & Temp at APH inlet, outlet & at ID Fan Outlet

• Temperature of Primary & Secondary Air at AH in/outlet

• Power Measurement – Mills & Fans

• Control Room Data

Measurement Locations

The number and type of instruments required for conducting this test depend on the unit being tested. The following table lists the measurement locations.

Measurement Temperature Gas Analysers Pressure

AH Gas Inlet Yes Yes Yes

AH Gas Outlet Yes Yes Yes

AH Air Inlet Yes Yes

AH Air Outlet Yes Yes

Rerence - cbip