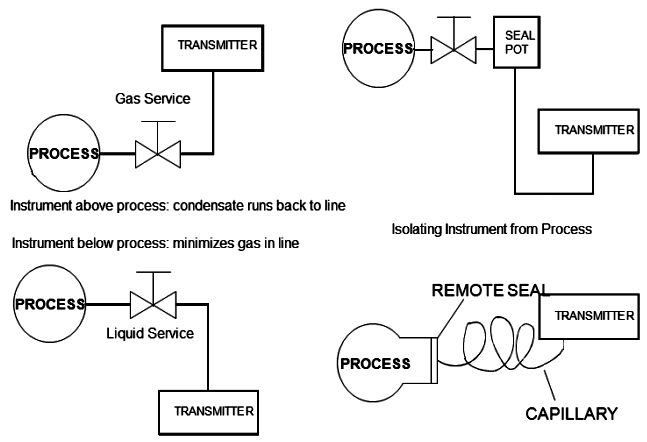

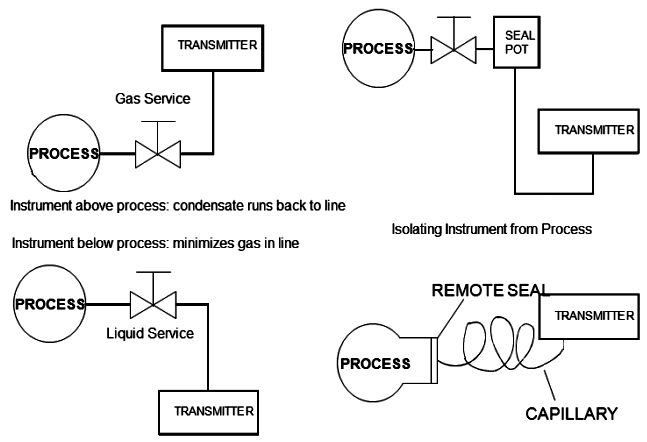

How to install a Pressure transmitter for different applications like gas, liquid and also in cases to separate the process from transmitter.

Installation of Pressure Transmitter

How to install a Pressure transmitter for different applications like gas, liquid and also in cases to separate the process from transmitter.

You did a great work by sharing this image. This will help to understand installation of pressure transmitter easily.

The way a pressure transmitter is mounted can depend on the nature of the process medium, namely whether it’s a gas, liquid, or steam.

The key objective is to ensure accurate pressure readings and to maintain the longevity of the transmitter.

Here’s a general guide:

Liquids: For liquid mediums, pressure transmitters are usually mounted below the process pipe. This allows the liquid to flow freely to the transmitter. When the system is shut down, the process fluid can drain away from the transmitter, avoiding possible damage from freezing if the liquid is susceptible to it.

Gases: For gas mediums, pressure transmitters are generally mounted above the process pipe. This orientation allows any condensed liquids to drain away from the transmitter. Condensed liquids in a gas system can accumulate and lead to inaccurate pressure readings.

Steam: When measuring steam pressure, pressure transmitters are often mounted alongside the process pipe and always include a “pigtail” or siphon loop (a pipe loop filled with water) between the process connection and the pressure transmitter. This loop helps to protect the instrument from the high temperature of the steam and avoid direct contact with it.

For all of these, it’s important to ensure that the transmitter is mounted securely and that all connections are properly sealed to prevent leaks. It’s also crucial to ensure that any mounting hardware can withstand the pressures and temperatures involved in the process.

These are only general principles. Always refer to the manufacturer’s instructions for specific mounting procedures.