The atmospheric tank’s difference is that the pressurized tank is an enclosed container with vapor pressure applied over the liquid, and the value of the vapor pressure may vary over time. Since the vapor pressure can not be neglected; therefore, it should be measured by both pressure inlets of the DP level transmitter. This could be accomplished by routing the vapor pressure into the top port using impulse piping.

There are two methods for this installation: Dry Leg and Wet Leg. The selection between both of them depends on the vapor properties.

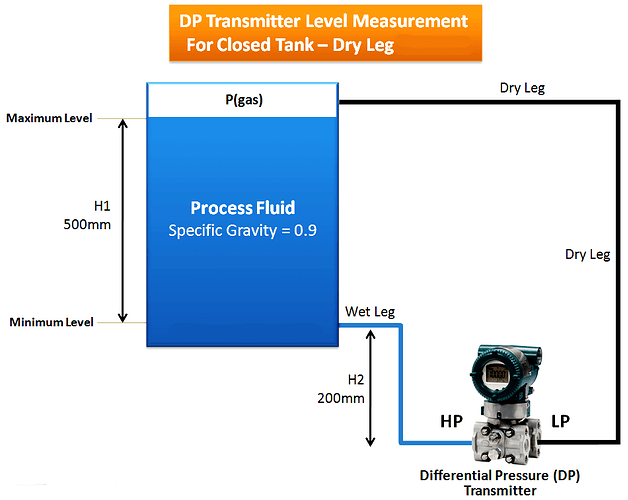

Dry Leg Level Measurement

Dry Leg Differential Pressure Level Measurement

When no vapor condensation, the Dry leg can be considered for the level measurements. The Upper tapped leg always dry, and no liquid needs to fill the upper leg. In this case, no additional liquid pressure will apply to a high port other than the vapor pressure. Hence, Top Port only measures the vapor pressure (see picture 1).

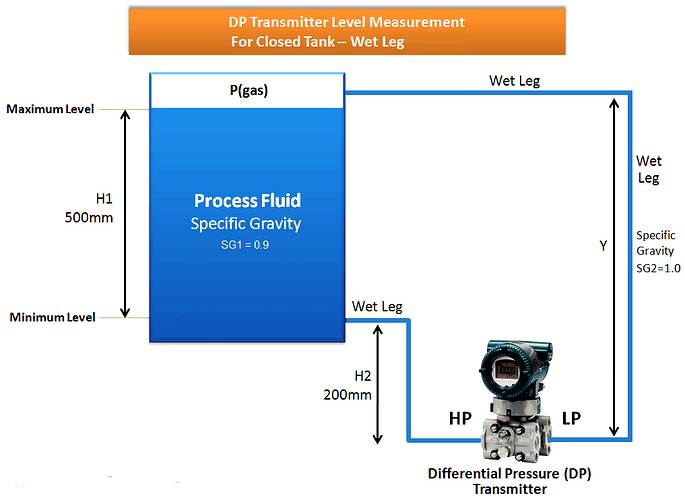

Wet Leg Level Measurement

Wet Leg Differential Pressure Level Measurement

Suppose condensation of the vapor is possible should choose the wet leg as the condensation would fill the leg and accumulate on the upper port side, which adds additional pressure resulting from condensate hydrostatic force.

In this situation, the upper leg shall fill with water or any liquid reaction to the liquid. Hence, the pressure from the upper port needs to be considered constant pressure in calculating the calibration range.

Conclusion

In conclusion, Wet Leg is still recommended in more of the level application to prevent unforeseen condensation in the top port.