Mass flow meters are the types of flowmeters which are mainly employed in mass-related processes such as chemical reactions, heat transfer, etc.

In all these processes, accurate measurement of flow is the prerequisite. There are numerous types of mass flowmeters available in the industry. However, the most widely used type is the Coriolis meter. Another type available is thermal type mass flowmeters

Coriolis Meter

A Coriolis meter works on Coriolis Effect, hence it is named so. Coriolis meters are considered to be true mass meters since they tend to measure the mass rate of flow directly while other flowmeter technologies measure volumetric flow.

Since mass does not change, no adjustments are needed for varying fluid characteristics. Hence, a Coriolis meter operates in linear fashion.

These types of meters exist in variety of designs. The most common type of unit includes

- a U-shaped flow tube

- a sensor assembly

- an electronics unit

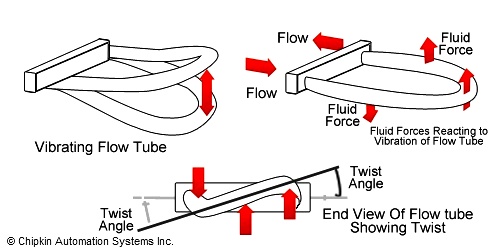

In this meter unit, the liquid passes through a U-shaped tube which vibrates in an angular harmonic oscillation. Coriolis forces will then deform the tube and a further vibration component gets added to the already oscillating tube. This added vibration element results in a phase shift or twist in few parts of the tubes.

This resulting phase shift which is directly proportional to the liquid mass flow rate is measured with the help of sensors. This measured information is further transferred to the electronics unit where it gets transformed to a voltage proportional to mass flow rate.

A Coriolis meter is shown in the figure below:

Advantages -

- A Coriolis meter can be applied for variety of applications ranging from adhesives and coatings to liquid nitrogen.

- Typical rangeability of curved tube designed Coriolis meters vary from 100:1 to 200:1 whereas for straight-tube meters its rangeability is limited i.e. about 30:1 to 50:1. Besides, accuracy of straight tube meters is low.

- In case of Coriolis meters, no compensation is needed for temperature and pressure variations. Also mass measurement is insensitive to changes in viscosity and density.

- They are particularly helpful for handling liquids whose viscosity changes according to velocity while temperature and pressure remains constant.

- These are called universal meters, since they are capable enough to measure nearly all liquids, slurries and gases. They can measure all liquid flows such as Newtonian, non-Newtonian and moderately dense gases as well.

- They can be employed to measure liquid density also.

- No Reynolds number restrictions are allied with Coriolis flow meters.

- They are also not affected by deformations in velocity profile.