-

The typical distillation column which is fed F moles/hr consists of two major components.

-

The material is separated in D moles/hr overhead or distillate product consisting of volatile products, and B moles/hr bottom products consisting of non-volatile products.

-

Main job is to adjust split between distillate and bottoms by controlling V/F ratio or D/F ratio.

-

Consider an example in which feed contains 50% benzene & 50 % toluene, and desired purity is 98% for both products. Normal value of D & B are moles/hr if feed is 100 moles/hr.

If D is increased to 52, overhead purity decreases to 96%.High purity products can be obtained by decreasing D but bottom would be very impure. -

If feed and composition is constant control can be achieved by regulating D or B.

-

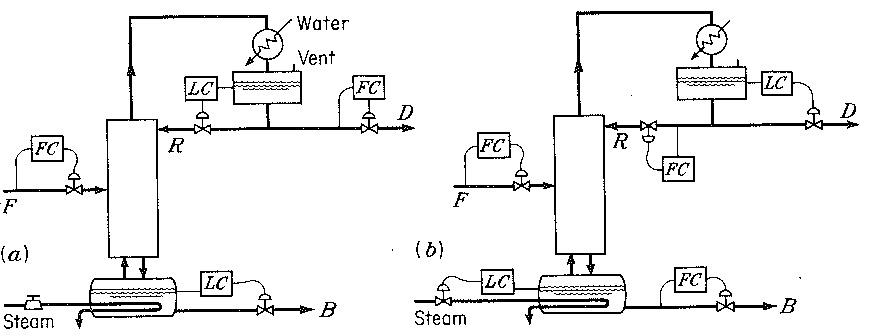

Bottom flow is regulated by constant level of reboiler(fig a).

-

Distillate flow is regulated by level in reflux drum(fig b).

4 Likes