Orifice plates require careful installation. The orifice plate coefficient is generally affected more by misalignments and disturbed velocity distributions than other differential-pressure meters because the abrupt pressure changes take place near the plate.

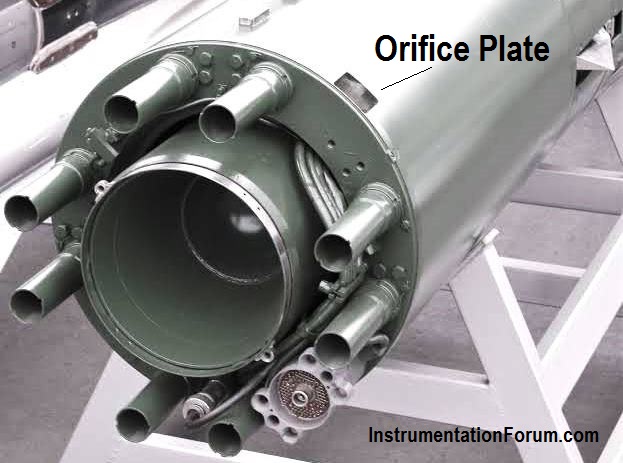

Orifice Plate

Poor installation of an otherwise properly designed orifice plate can cause as much as a 20-percent error (Humphreys, 1987). The orifice plate should be mounted in such a way that it is possible to inspect at least the orifice plate and preferably the adjacent piping.

The orifice hole diameter should be at least 0.5 in, and its upstream edge should be free of visible dents, burrs, and rounding.

The orifice hole must be bored perpendicular to the plate. The bore hole cylinder length must be between 0.005 and 0.02 times the pipe diameter ( D ). If the plate is thicker than 0.02 D , the downstream orifice must be beveled at an angle between 30 to 60 degrees from horizontal. Centering of the plate orifice hole, as specified in the standard, is particularly difficult to meet for small pipes.

The plate shall be mounted perpendicular to the pipe axis. The orifice plate material should be thick enough so it will not bow under the differential pressure.

The plate faces shall be flat and parallel. The plate thickness shall be less than 0.05 times the pipe diameter, and its upstream face shall be have a quality finish.