CONSTRUCTION

-

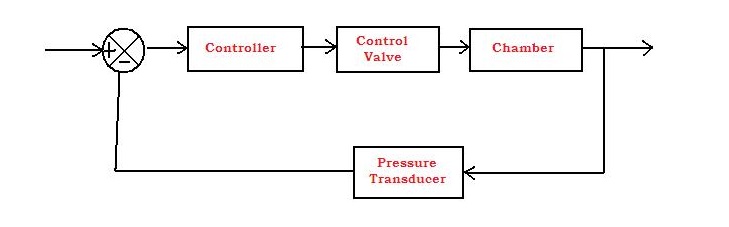

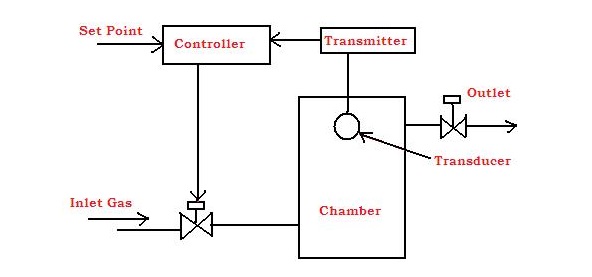

The pressure control system is mainly consists of a chamber (plant).

-

The pressure sensor is placed in the chamber.

-

The sensor is connected to the transmitter, where the signal is to be processed.

-

The transmitter is connected to the controller.

-

The controller is connected to the control valve, where the flow of gas is to be controlled.

WORKING

If the pressure in the tank is increased above the set point value, then the present pressure in the tank is sensed by the pressure sensor. The sensor converts the pressure into the electrical signal. Then that electrical signal is processed to the transmitter, where the signal is to be measured. That signal is processed to the controller where the signal is compared with the set point value. Then the control valve will be closed and pressure is decreased to the set point value.

If the pressure in the tank is decreased , then the present pressure in the tank is sensed by the pressure sensor. The sensor converts the pressure into the electrical signal. Then that electrical signal is processed to the transmitter, where the signal is to be measured. That signal is processed to the controller where the signal is compared with the set point value. Then the control valve will be opened and the pressure will increased near the set point value.

Author: Laxmi Omprakash Singh