There are four common components on most bubbler level systems that are prone to fail as time goes by. Any of these failures may prevent the bubbler system from operating correctly.

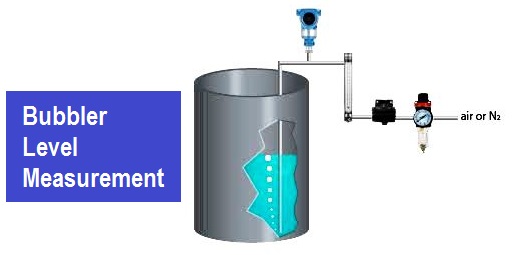

Bubbler Level Measurement

They are as follow.

Blocked Bubbler Probe Tube

If possible, visually inspect the stainless steel cable on the bubbler probe assembly for any signs of damage. Verify that the probe is secured to the wet well.

Typically, the periodic purging cycle will keep the bubbler tube free of material and functioning properly. If material in the wet well causes a tube blockage, then the controller will detect a reduction in air flow and will execute a purging sequence automatically.

If the unit cannot clear the blockage, then the system will try to continue purging the bubbler tube.

If an obstruction is suspected, then disconnect the bubbler tube from the unit to see if the purging sequence is completed and the unit returns to normal operation (unit should measure zero level). If it does, most likely there is a blockage inside the bubbler tube.

Clogged Filter / Flow Restrictor

The flow restrictor is protected by a dust filter but may become clogged with dust or other particles found in the air.

Any obstructions inside of the filter will cause the air flow to decrease and may even affect the accuracy of the level measurement.

The best way to check for this is to replace the filter / flow restrictor with a new one.

Air Compressor Failure

These units are designed to automatically detect and indicate air compressor failures.

The defective air compressor should be replaced. If the problem persists, then the failure could be caused by an air leak, a defective solenoid, or the unit itself.

Air Leaks

Any air leaks within the system may affect the accuracy of the level being measured and could potentially cause the entire system to fail.

They are usually caused by improperly sealing tubing connections or damaged tubing. To check for an air leak, disconnect the bubbler tube from the unit and replace it with a pressure gauge (if available).

Verify that this connection is properly sealed. If the unit starts its purging sequence and the pressure either increases or remains stable, then there are no leaks. If the pressure decreases, then there could be an air leak within the system.