The term “Rotameter” was derived from the fact that floats originally were produced with slots to give them rotation for the purpose of centering and stabilizing the float. The essential elements of any rotameter are listed as follows. In addition to suitable inlet and outlet connections, they comprise

(1) a metering tube and (2) a float.

1. Metering Tubes

In modern practice, they are formed on a mandrel and annealed to prevent internal stresses so that strong, uniform tubes result. This method also permit the forming of tubes with greater reproducibility and interchangeability and forming special shapes, such as non conical tubes with curved elements designed to spread out the graduations at the lower end of the range. It is possible to modify the conical form slightly in order to give the exact linear relationship between aperture and float position which is not quite achieved with a purely conical tube.

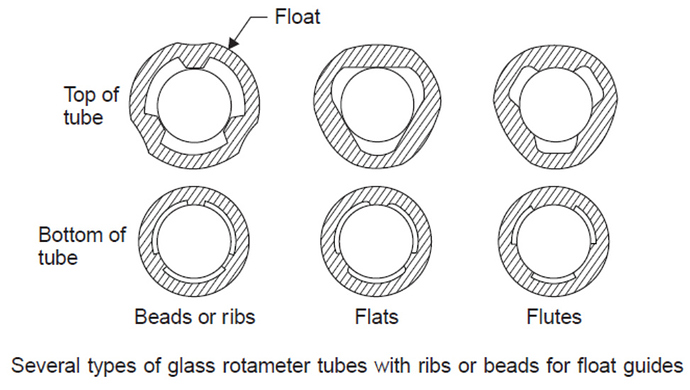

The most important special shape is a modified conical section having internal beading or lands which serve to guide the float. Fig. shows some types of glass rotameter tubes with ribs or beads for float guides.

2. Floats.

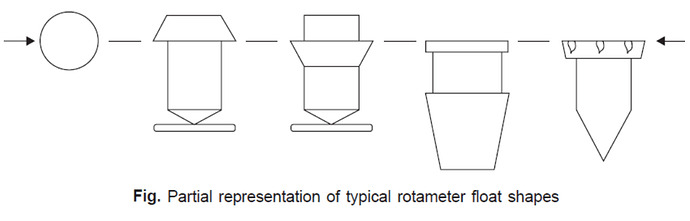

Floats can be made from several materials to obtain corrosion resistance or capacity modification. Ratings are generally in terms of meter capacity, using a stainless steel float. It has been found that the float shape determines to a large extend of how much a rotameter will be influenced by changes in the viscosity of the measured fluid. Floats having sharp edges have been found to be relatively insensitive to viscosity changes over a considerable viscosity range. Some typical float shapes are shown in Fig.