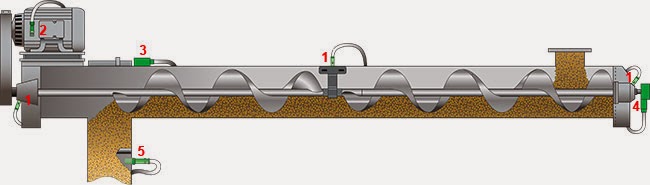

It consists of helicoid (helical flights rolled from flat steel bar) flight, mounted on a pipe on or shaft and turning in a trough. Screw conveyors are preferably used to transport and to dose powder, fine grain or fibrous materials.

Parts of screw conveyor:

- Shaft

- Drive

- Trough

- Helical flights

- Hanger

Classification of screw conveyors by its line of transport:

a. Horizontal screw conveyor.

b. Angular screw conveyor.

c. Vertical screw conveyor.

Principle of operation: The intake end of conveyor is fed with a continuous supply of particulate material. The rotating screw in the trough or pipe will lift the material by a wedging action. The screw will be rotated by drive and supported on bearings. The screws are constructed in different fashion for special applications.

Preventive Maintenance points:

1.Grease or oil filling of the gears or geared motor as recommended by the manufacturer.

2.Re-lubrication of bearings as per the requirement.

3.The packing adjustment at the shaft passages of the screw conveyor.

4.The chain drives cleaning with petroleum or p-3 solution and then applying grease or oil as per the recommendation of the supplier.

5.Cleaning the screw conveyor depending upon the material in certain intervals, if found necessary.