Study about Sequential Logic Control in Programmable Logic Controllers (PLC) an their applications in ladder logics.

Discrete-State Control

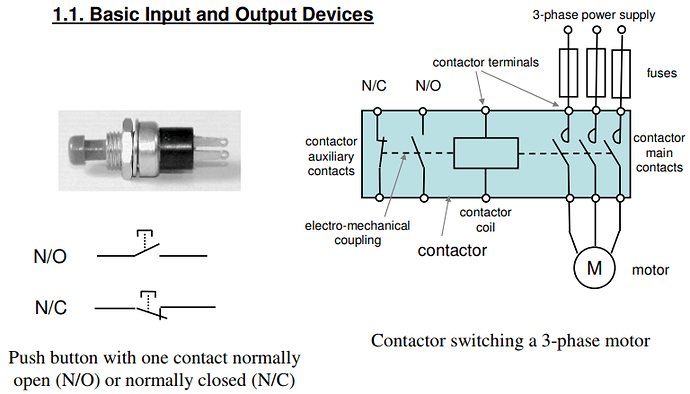

Basic Input and Output Devices

Discrete-State Process Control

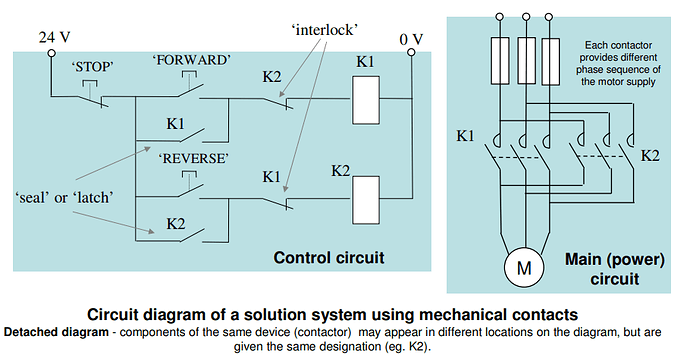

Example 1.1. Simple Forward-Reverse Motor Control

Design a control system that allows the operation of a motor in two directions of rotation. Two relays or contactors are used in the supply circuit of the motor. The control system has two START pushbuttons, one for each direction, and a single STOP pushbutton.

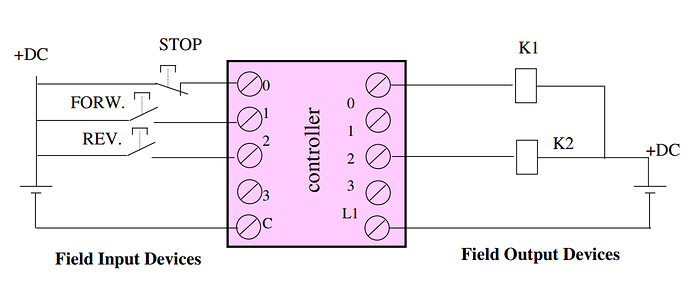

Circuit diagram of a solution system using electronic controller

There are three input variables and two output variables of the controlled process: FORV, REV, STOP, K1 and K2.

All variables are discrete, i.e. can assume only two values: ON or OFF.

A particular combination of the values of all variables defines the discrete state of the system, eg.: (FORW=on, REV=off, STOP=on, K1=on, K2=off).

Not all possible states are permissible; eg. the state (FORW=off, REV=off, STOP=on, K1=on, K2=on) would result in a short circuit in the mains supply!

There is a prescribed sequence in which the states can occur.

For example, the state (FORW=off, REV=off, STOP=on, K1=on, K2=off) is always preceded by the state (FORW=on, REV=off, STOP=on, K1=on, K2=off) .

The described control function is provided by the controller. This is the case of discrete-state process control or sequential logic control.