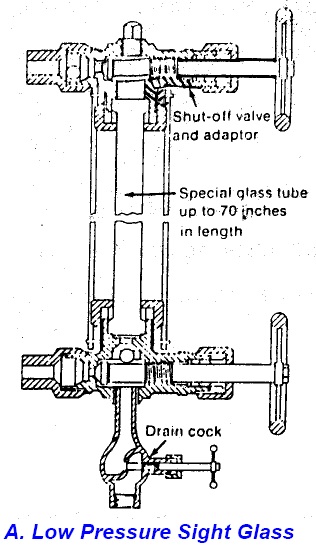

Another simple method is called sight glass (or level glass). It is quite straightforward in use, the level in the glass seeks the same position as the level in the tanks. It provides a continuous visual indication of liquid level in a process vessel or a small tank and are more convenient than dip stick, dip rod and manual gauging tapes.

Sight glass A is more suitable for gauging an open tank. A metal ball normal used in the tube to prevent the fluid from flowing out of the gauge. Tubular glass of this sort is available in lenghts up to 70 inches and for pressure up to 600 psi. It is now seldom used.

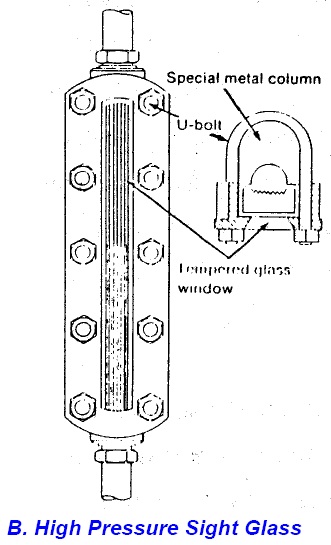

The closed tank sight glass B, sometimes called a ‘relfex glass’, is used in many pressurized and atmospheric processes. The greatest use is in pressurised vessel such as boiler drums, evaporators, condensers, stills, tanks, distillation columns, and other such applications.The length of reflex glass gauges ranges from a few inches or eight feet, but like the tube type gauges, they can be gauge together to provide nearly any length of level measurement.

The simplicity and reliability of gauge type level measurement results in he use of such devices for local indication. When level transmitters fail or must be out of service for maintenance, or during times of power failure, this method allow the process be measured and controlled by manual means.

However, glass elements can get dirty and are susceptible to breakage thus presenting a safety hazard especially when hot, corrosive or flammable liquids are being handled.