Commonly identified with electrical equipment monitoring, thermography is also a useful tool for monitoring plant machinery.

Thermography measures infrared radiation energy emissions (surface temperatures) to detect anomalies. Infrared cameras have resolution to within 0.1 °C and digitally store captured images.

Both the absolute and relative temperatures can be obtained on virtually all types of electrical equipment, including switchgear, connections, distribution lines, transformers motors, generators and bus work.

This technique is very popular because of the following reasons:

• It is a non-contact type technique

• Fast, reliable and accurate output

• A large surface area can be scanned quickly

• It can be easily scanned from a distance up to 50 m.

• Presented in visual and digital form

• Software back-up for image processing and analysis

• Requires very little skill for monitoring

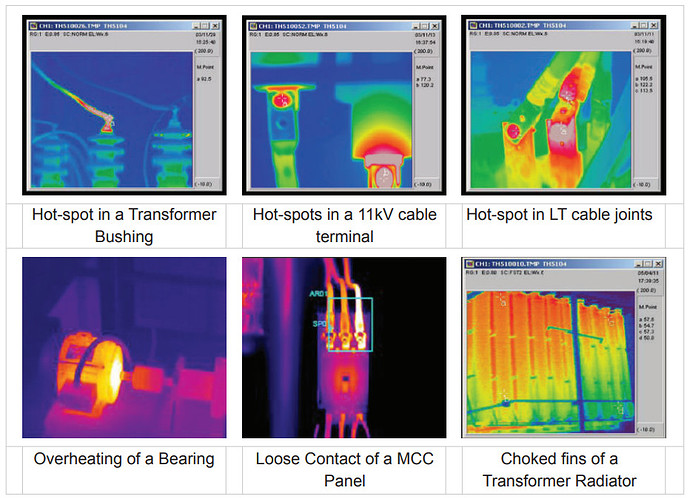

This technique can be used very well for seeing the loose contact, corrosive contact of all types of electrical joints, body temperature of motor and transformers, panels, etc.

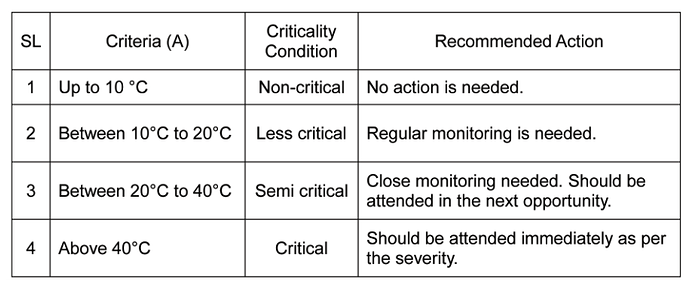

The criteria shown in Table may be used to know the severity of the problem.

The typical thermographic measurements are illustrated in Figure overleaf.