Three way manifold valve operation

-

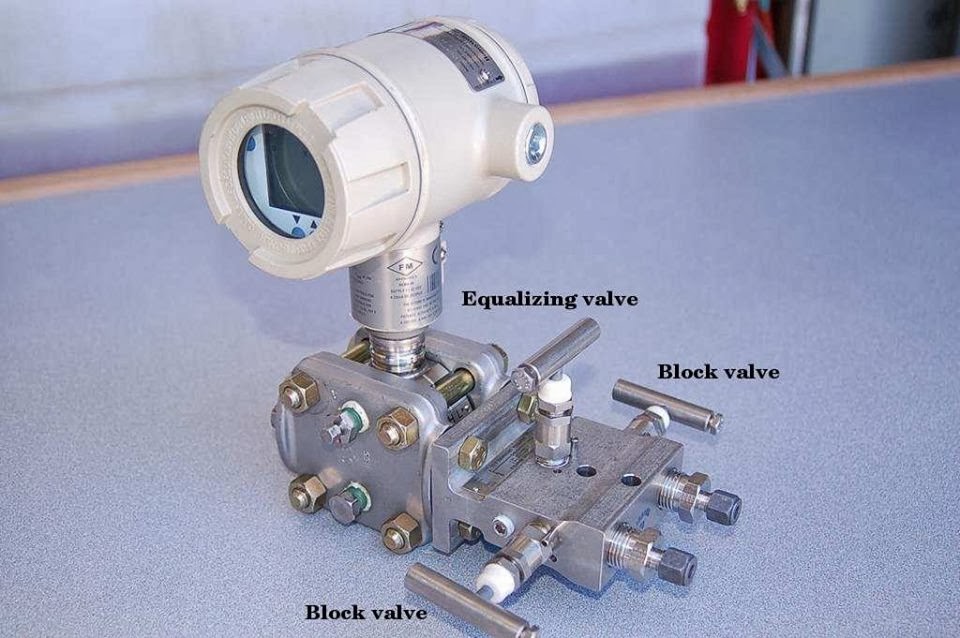

The following photograph shows a three-valve manifold bolted to a Honeywell model ST3000 differential pressure transmitter.

-

A bleed valve fitting may be seen inserted into the upper port on the nearest diaphragm capsule flange.

-

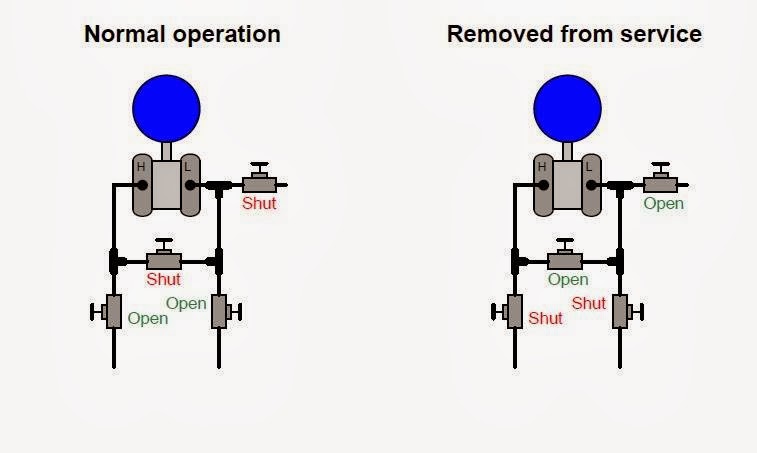

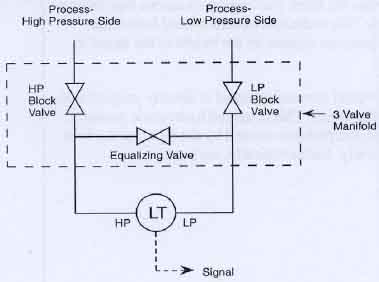

In normal operation, the two block valves are left open to allow process fluid pressure to reach the transmitter.

-

The equalizing valve is left tightly shut so no fluid can pass between the “high” and “low” pressure sides.

-

To isolate the transmitter from the process for maintenance, one must close the block valves and open the equalizing valve.

-

The best sequence to follow is to first close the high-pressure block valve, then open the equalizing valve, then close the low-pressure block valve.

-

This sequence ensures the transmitter cannot be exposed to a high differential pressure during the isolation procedure, and that the trapped fluid pressure inside the transmitter will be as low as possible prior to “venting” to atmosphere.

-

Finally, the “bleed” valve is opened at the very last step to relieve pent-up fluid pressure within the manifold and transmitter chambers.