Mechanical

A mechanical actuator functions to execute movement by converting one kind of motion, such as rotary motion, into another kind, such as linear motion.

An example is a rack and pinion. The operation of mechanical actuators is based on combinations of structural components, such as gears and rails, or pulleys and chains.

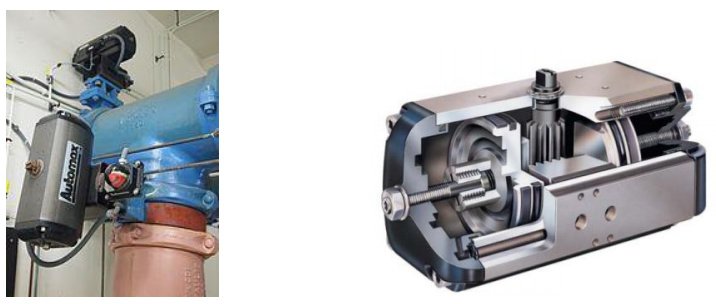

A rack and pinion with two racks and one pinion is used in actuators. An example is pneumatic rack and pinion actuators that can be used to control valves in pipeline transport. The actuators in the figure are used to control the valves of large water pipeline.

In the top actuator, a gray control signal line can be seen connecting to a solenoid valve (the small black box attached to the back of the top actuator), which is used as the pilot for the actuator. The solenoid

valve controls the air pressure coming from the input air line (the small green tube). The output air from the solenoid valve is fed to the chamber in the middle of the actuator, increasing the pressure. The pressure in the actuator’s chamber pushes the pistons away. While the pistons are moving apart from each other, the attached racks are also moved along the pistons in the opposite directions of the two racks. The two racks are meshed to a pinion at the direct opposite teeth of the pinion. When the two racks move, the pinion is turned, causing the attached main valve of the water pipe to turn.

Pneumatic (Diaphragm, piston),

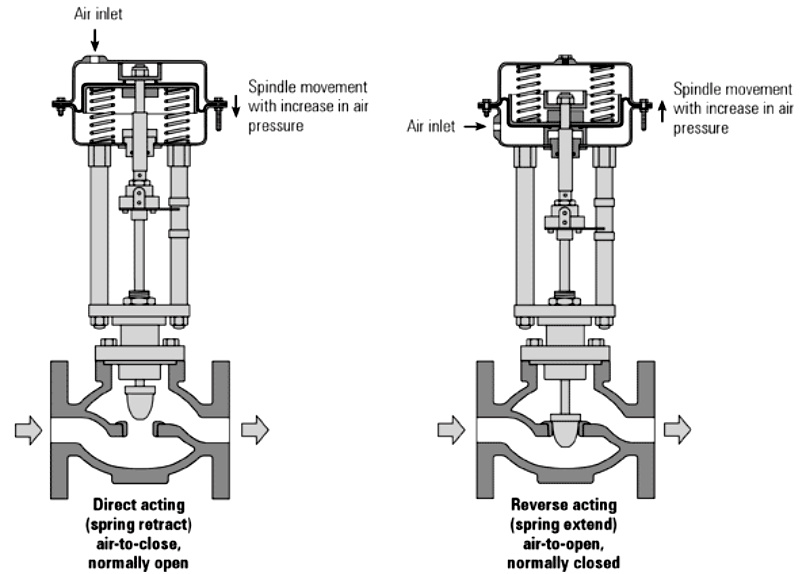

A pneumatic actuator converts energy formed by vacuum or compressed air at high pressure into either linear or rotary motion. Pneumatic energy is desirable for main engine controls because it can quickly respond in starting and stopping as the power source does not need to be stored in reserve for operation.

Pneumatic actuators enable considerable forces to be produced from relatively small pressure changes. These forces are often used with valves to move diaphragms to affect the flow of liquid through the valve.

Hydraulic

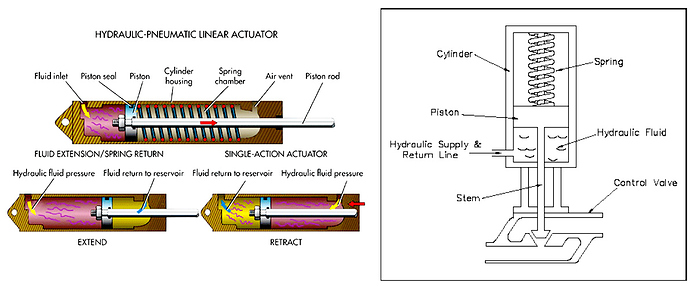

A hydraulic actuator consists of cylinder or fluid motor that uses hydraulic power to facilitate mechanical operation. The mechanical motion gives an output in terms of linear, rotatory or oscillatory motion. As liquids are nearly impossible to compress, a hydraulic actuator can exert a large force. The drawback of this approach is its limited acceleration.

The hydraulic cylinder consists of a hollow cylindrical tube along which a piston can slide. The term single acting is used when the fluid pressure is applied to just one side of the piston. The piston can move in only one direction, a spring being frequently used to give the piston a return stroke. The term double acting is used when pressure is applied on each side of the piston; any difference in pressure between the two sides of the piston moves the piston to one side or the other