There is a class of flow meters which use the pressure drop caused by an obstruction in the flow in a unique way. These meters, call variable area flow meters depend on the flow of the fluid to carry an object along. In a fixed diameter pipe, the object would be carried along with the flow based on the resistance to that flow.

If the flow is moving in a variable diameter pipe, the force on that object changes with changes in the pipe diameter, and hence, the clearance between the sides of the object and the sides of the pipe. This class of flowmeters is generally represented by two main types; Rotameters and spring – plunger meters.

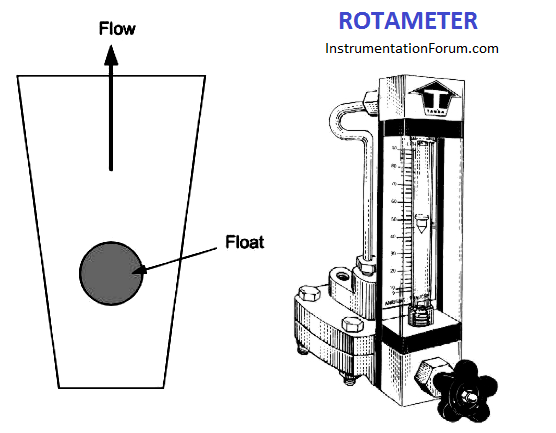

Rotameter

The rotameter is a variable area meter that employs a vertical tube of varying diameter, with an object inserted in it. This object is known as the float. This type meter is used only in a vertical position, as gravity is a primary force involved in the calibration the device.

The float is moved vertically in the variable diameter tube by a combination of buoyancy forces and flow pressure forces. The flow pressure forces are created by the fluid try in move around the float, by using the gap between the float and the sides of the tube.

As the forces move the float up the tube, the widening gap between the tube and the float allow these forces to be reduced, and gravity tends to force the float back down the tube toward the bottom.

At the equilibrium point for a given flow, the forces of flow and buoyancy in the vertical direction are balanced the mass of the float being pulled down by gravity.

Credits - Mitchell Cottrell