Supervisory control and data acquisition (SCADA) systems are centralized control systems that monitor, collect and process data from sensors placed throughout a factory or remote field location.

Function of SCADA system

SCADA systems are used in a variety of industries such as traffic systems, electric power utilities and mass transit systems where equipment functions must be closely monitored and controlled automatically. SCADA systems can collect data from sensors as well as send control signals back to the equipment being monitored.

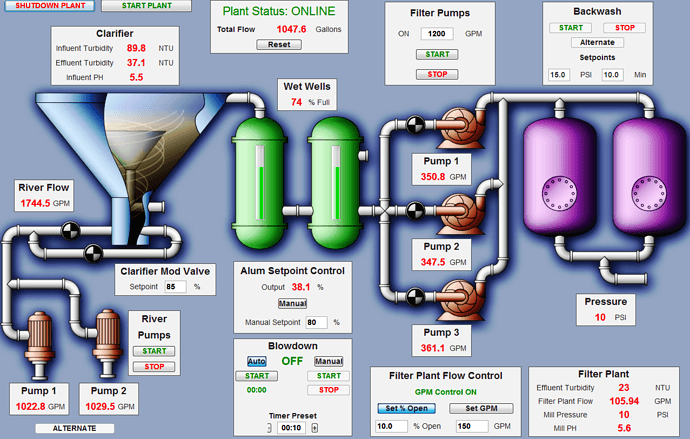

SCADA systems perform several functions. The three basic functions are the monitoring, control and user interface functions. The monitoring function collects data and sends it back to the central computer. The control function gathers data from monitoring sensors, processes it and send control signals back to the equipment according to a prescribed software program. The user interface is often a large control room where individuals can monitor SCADA input and output responses in real time.

SCADA is not just pictorial view of the plant but much more.

SCADA= S upervisory C ontrol A nd Data A cquisition.

It has graphical user interface which displays critical control and process flow at centralized control room.

This gives ability to the process engineers a bird’s eye view on whats happening in the process. For e.g. current/past values/trends of the process variables such as temperature, pressure, humidity etc are displayed.

Also, if required, process engineer can change ‘control set point’ of the process parameters from centralized control room.

In short process engineer can view or change process parameters from centralized location through graphical interface.

Second important aspect of SCADA is Data Acquisition. Vital information of the process is collected and stored for analysis.