Manifolds are equipment which connects two or more valves of a hydraulic system.

A variety of block/isolate valves can be combined in a single body configuration. Each of these valves has a separate opening below in order to connect a pipe. The main body or valve chamber is common to all.

These manifolds commonly include ball, bleed, needle, and vent valves. Their use results in savings in terms of space and installation costs.

Manifold Valve

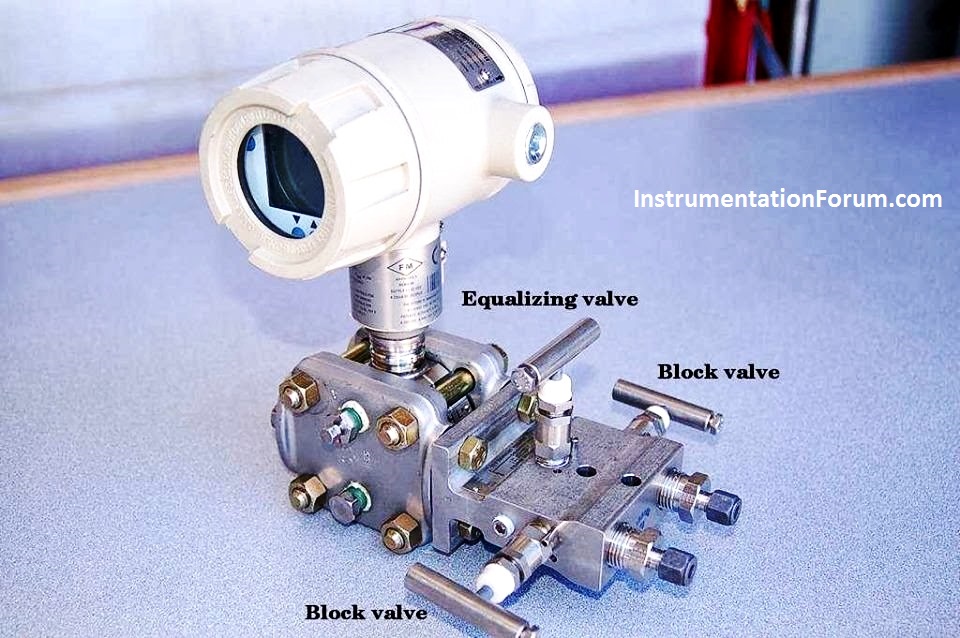

The following photograph shows a three-valve manifold bolted to a Honeywell model ST3000 differential pressure transmitter.

A bleed valve fitting may be seen inserted into the upper port on the nearest diaphragm capsule flange.

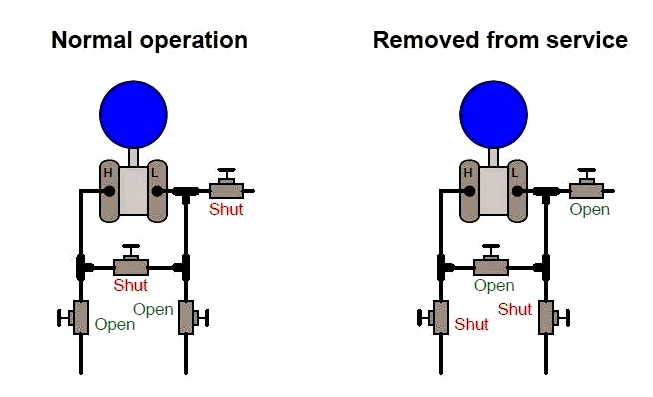

In normal operation, the two block valves are left open to allow process fluid pressure to reach the transmitter.

The equalizing valve is left tightly shut so no fluid can pass between the “high” and “low” pressure sides.

To isolate the transmitter from the process for maintenance, one must close the block valves and open the equalizing valve.

The best sequence to follow is to first close the high-pressure block valve, then open the equalizing valve, then close the low-pressure block valve.

This sequence ensures the transmitter cannot be exposed to a high differential pressure during the isolation procedure, and that the trapped fluid pressure inside the transmitter will

be as low as possible prior to “venting” to atmosphere.

Finally, the “bleed” valve is opened at the very last step to relieve pent-up fluid pressure within the manifold and transmitter chambers.