PLC stands for programmable logic controller, It is a control device built similarly to a computer that can be programmed for using automation of electro-mechanical processes such as control of machinery in factory assembly lines, oil refineries, waste water treatment plants, pharmaceutical manufacturing plants, cement plants, paper & pulp industries etc.

In earlier days, The machinery was operated and controlled using hardwired panels. The plc replaced hardwired relays in the late 1960’s.

The advantages of plc over hardwired relays are,

-

Less cabling

-

Fast response time

-

High reliability

-

Easy troubleshooting

-

Highly flexible and easy to change logics

-

Less installation space required

-

Communication ans interfacing with other systems

-

Security

What is PLC?

The above diagram shows us the basic operation of plc. In the diagram we can see that all the input sensing devices such as Pressure & Temperature sensors, Flow rate sensors are sending its signal to the controller which is analog(4-20mA)in nature.

As i said in my previous post on DCS, All the control systems must be first convert analog input data into digital form before it can be processed & similarly the processed digital output data must be convert into analog form. Why we preferrably use 4-20mA rather than 0-5V or 0-20mA will be discuss in next post.

PLC is programmed using different types of programming languages such as Ladder logics, FBD’s(functional block diagrams), Instruction List, Structured Text. Most of the plc programmers use Ladder Logics because it is easy to understand. The plc is only programmed in PC’s or Laptop by installing its software in it.

After programming, The user will download the program into CPU of the system. The updation & troubleshooting of the program can only be done in the PC. The uploading and downloading of the program between plc<---->pc is done through serial ports, Ethernet cable, RS232, RS422/485 etc.

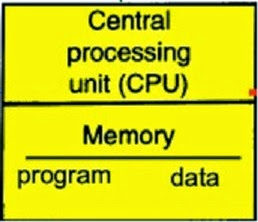

Controlling process is supervised by a program stored in the memory of the system.

PLC has two types of memory,

1)RAM

2)EPROM

RAM stores the Application program and values of internal variables, timers, counters, shift registers etc. Processor takes the data from RAM and executes the logic(written in RAM). EPROM saves the application program only. In case of loss of memory in RAM, EPROM transfers the program to RAM. EPROM needs updation on every change in the program.

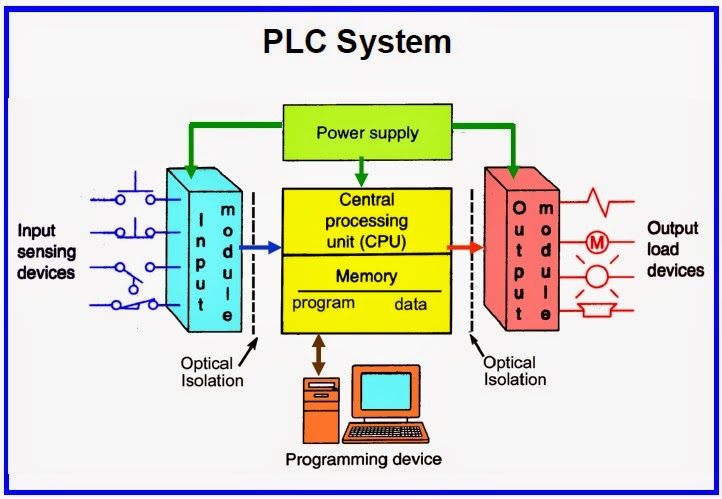

The basic components of PLC are,

1)Power Supply

2)Input module

3)CPU

4)Output module

In the above diagram, We can see the architecture of a plc system. Lets go to the functionalities of every component of plc.

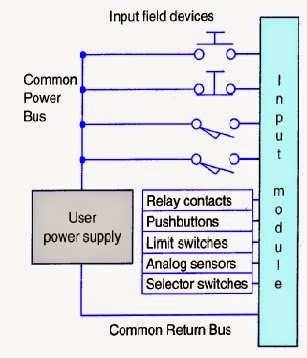

INPUT MODULE:

As we see in the figure, Input module receives the signals from input field devices such as sensors, pushbuttons and sends them to the CPU of the system for processing. All the input field devices are physically wired to the input module.

CPU:

CPU is the brain of the PLC, It takes the input data from various sensing devices through the input module and executes the stored program in the memory and sends an appropriate output command to the output module to control the output devices.

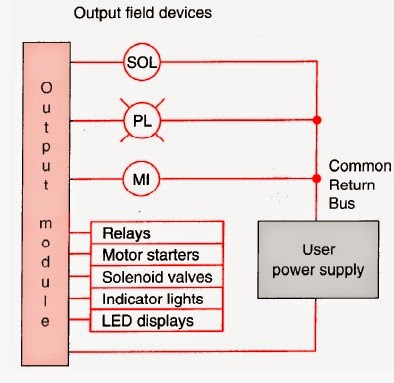

OUTPUT MODULE:

This module receives commands from the CPU of the system and send a output signal to the field devices such as motors, solenoid valves to change its state.

NEED OF HMI FOR PLC:

In PLC we can’t monitor the process in pc using its programming software. For viewing the process undergoing in the field we requires HMI.

It stands for Human Machine Interface, It is an operator interface used for viewing the process, taking actions on process, trending, alarming, and keeping historical data of trends, alarms etc. It can be modular or pc based.

It communicates with plc and read/writes data from/to the plc. More than one plc can be connected to hmi and it can locate far away from plc.

COMMUNICATION AND INTERFACING OF PLC:

PLC is highly flexible in communication and interfacing with other devices and systems. It is possible to communicate and interface between,

PLC<—>PLC

PLC<—>DCS

PLC<—>SCADA

PLC<—>HMI

PLC<—>VSD(variable speed drive)

REDUNDANCY IN PLC:

Redundancy is the duplication of critical components or functions of the systems with the aim of increasing reliability, back-up and fail-safe.

Most PLC vendors provide units with build-in redundancy for processor and power supply. There are three types of redundancy.

1) COLD STANDBY:

In this type of redundancy, If the master sytem fails then the slave will manually start for taking control action.

2) HOT STANDBY:

In this type of redundancy, Both the master and slave systems are running continuously and processes the I/O’s parallelly, If the master system fails, Slave system will take charge automatically without interrupting the control process in the plant.

3) TMR (triple modular redundancy):

In this type of redundancy three systems will work parallelly and output is getting delivered based on 2oo3(2 out of 3) voting. This type of redundancy is used in highly hazardous and critical applications(explosive gas plants,nuclear power plants etc)