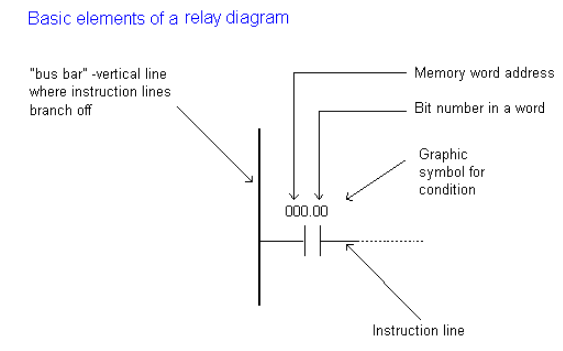

There are several languages designed for user communication with a PLC, among which ladder diagram is the most popular. Ladder diagram consists of one vertical line found on the left hand side, and lines which branch off to the right. Line on the left is called a “bus bar”, and lines that branch off to the right are instruction lines.

Conditions which lead to instructions positioned at the right edge of a diagram are stored along instruction lines. Logical combination of these conditions determines when and in what way instruction on the right will execute. Basic elements of a relay diagram can be seen in the following picture.

Most instructions require at least one operand, and often more than one. Operand can be some memory location, one memory location bit, or some numeric value -number. In the example above, operand is bit 0 of memory location. In a case when we wish to proclaim a constant as an operand, designation # is used beneath the numeric writing (for a compiler to know it is a constant and not an address.) Based on the picture above, one should note that a ladder diagram consists of two basic parts: left section also called conditional, and a right section which has instructions. When a condition is fulfilled, instruction is executed, and that’s all!

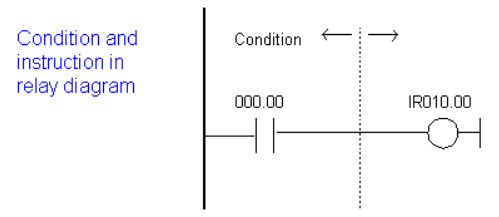

Picture above represents a example of a ladder diagram where relay is activated in PLC controller when signal appears at input line 00. Vertical line pairs are called conditions. Each condition in a ladder diagram has a value ON or OFF, depending on a bit status assigned to it. In this case, this bit is also physically present as an input line (screw terminal) to a PLC controller. If a key is attached to a corresponding screw terminal, you can change bit status from a logic one status to a logic zero status, and vice versa. Status of logic one is usually designated as “ON”, and status of logic zero as “OFF”.

Right section of a ladder diagram is an instruction which is executed if left condition is fulfilled. There are several types of instructions that could easily be divided into simple and complex.

Example of a simple instruction is activation of some bit in memory location. In the example above, this bit has physical connotation because it is connected with a relay inside a PLC controller. When a CPU activates one of the leading four bits in a word IR010, relay contacts move and connect lines attached to it. In this case, these are the lines connected to a screw terminal marked as 00 and to one of COM screw terminals.