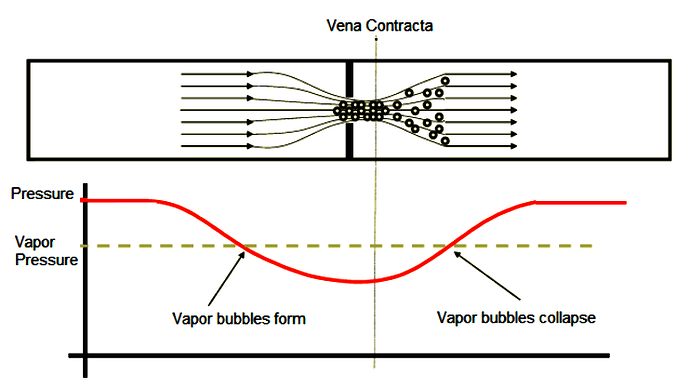

Cavitation is similar to flashing in a way that the liquid pressure drops to value below its vapor pressure, causing a liquid to vaporize into vapor bubbles.

Both cavitation and flashing occurs because the pressure energy in a fluid is converted to kinetic energy due to the contraction at the valve closure member, causing an increase in velocity.

In addition, as the temperature of the liquid increases, the likelihood of cavitation becomes more likely because of the increased vapor pressure.

The extent of the cavitation depends mainly on the downstream pressure and the differential pressure across the valve.

Valve Cavitation

The difference is that with the cavitation phenomenon, the liquid pressure increases over its vapor pressure during pressure recovery and turns back into liquid state while during flashing the liquid pressure remains below the vapor pressure throughout.

How to avoid Cavitation:

If cavitation is ever encountered, consider the following corrective actions:

-

The first is to equip the control valve with special trim and ensure that the plug and seat are made of a hard facing material that can resist both the onset and effect of cavitation (e.g. stellite hard facing).

-

The second is to use a valve with a low recovery coefficient (see below).

-

The third is to increase the downstream pressure by installing a flow restrictor if possible or reducing the pipe size of a short piece downstream.