Advantages of Human Machine Interface (HMI)

- These allow control systems to be much more interactive than before.

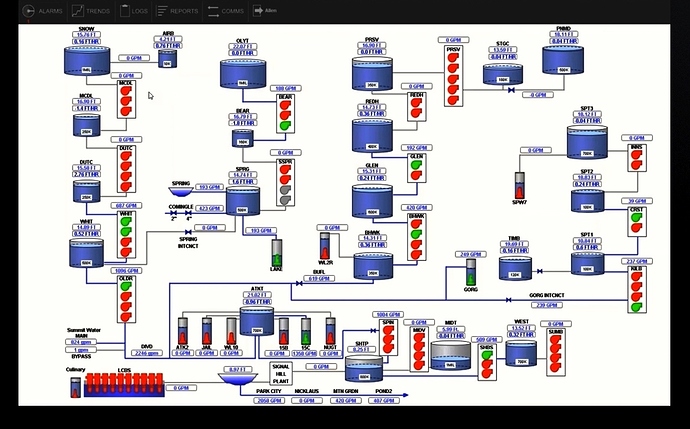

- The basic purpose of an HMI is to allow easy graphical interface with a process.

These devices have been known by a number of names,

- touch screens

- displays

- Man Machine Interface (MMI)

- Human Machine Interface (HMI)

These allow an operator to use simple displays to determine machine condition and make simple settings.

The most common uses are,

- display machine faults

- display machine status

- allow the operator to start and stop cycles

- monitor part counts

These devices allow certain advantages such as,

- color coding allows for easy identification (eg. red for trouble)

- pictures/icons allow fast recognition

- use of pictures eases problems of illiteracy

- screen can be changed to allow different levels of information and access

The general implementation steps are,

- Layout screens on PC based software.

- Download the screens to the HMI unit.

- Connect the unit to a PLC.

- Read and write to the HMI using PLC memory locations to get input and update screens.

To control the HMI from a PLC the user inputs set bits in the PLC memory, and other bits in the PLC memory can be set to turn on/off items on the HMI screen.