Capacitance type : Indirect level measurement

Capacitance is the property of a circuit that stores electrons and thus opposes a change in voltage in the circuit. A capacitor is an electrical component that consists of two conductors separated by a dielectricic or insulator. The capacitance value of a capacitor is measured in Farads (F), and the value is determined by the area of the conductors (usually called plates ), the distance between the plates, and the dielectric constant of the insulator between the plates.

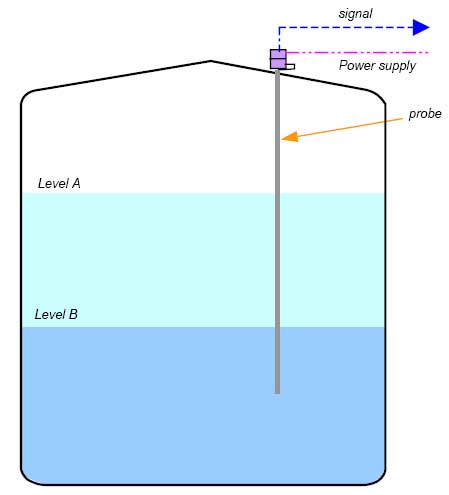

Generally, one thinks of a capacitor as having two small parallel plates separated by air or another type of dielectric. For capacitance level measuring applications, however, one plate is a probe while the other plate is comprised of the tank of the level vessel ( see figure of capacitance below ). The dielectric is the material in the vessel which will determined the capacitance value when it rises and falls. The liquid in the tank will be measured by the capacitance measurement meter. Capacitance level measurement probes are mostly used in on /off applications for alarms or switches and control functions. For such applications, the probes can be mounted horizontally, perpendicular to the level surface, so that a large plate area is effectively used.

Capacitance level measurement devices play an important role in the manufacturing and processing industries, but under some operating parameters they require special consideration.

Generally, the capacitance values of a probe should be high compared to the capacitance of the lead wires connecting it to the measuring circuit. The wire capacitance should be swamped by the

probe capacitance variations. Otherwise, instability and erratic operation may result.

Some advantages of capacitance level devices are the following :=

· They contain no moving parts

· Simple and rugged design is possible

· Design for corrosive application is possible

· Generally, they are easy to clean

· Sanitary design is available for the food processing industry.

· Extreme temperature and pressure requirements are possible by careful design

· They can be designed for explosion proof service

As is true with most measuring systems, certain limitations do exist for capacitance level techniques. The following are some of the most notable :

· · Measurement is subject to error caused by temperature changes affecting the dielectric constant of the material to be measured

· Coating of the probe by conductive material causes error in measurement. An example of this is the condensation of water vapor in the vapor phase of a vessel, forming water droplets on the probe

· Usually empirical calibration techniques are used

· In solids measurement, variations in particle size affect the dielectric constant