Flow measurement is a primary requirement of most piping systems. Though it is a simple task to determine the quantity of flow; frequently it poses significant challenges.

Multi-hole orifice plate is mostly used as throttle element. Compared to single-hole orifices multi-hole orifices have smaller orifice sizes and various patterns of orifice distribution.

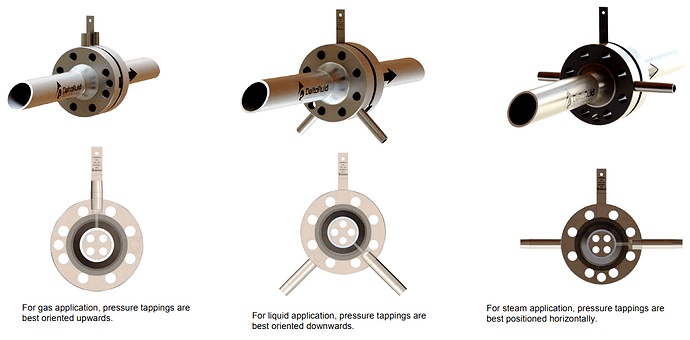

Multi-Hole Orifice Plate

For a single-hole orifice plate there is no neighbor turbulence that choke the pressure recovery, in case of multiple-hole orifice plate the expansions of one jet will impact with the expansions of the others limiting the pressure recovery.

A series of throttle tests in water flow is conducted to investigate the effect of various geometric features like the total orifice number, orifice with different configurations, aspect ratio, Diameter ratio, and throttling effect in multi stage assembly on the pressure loss characteristics of multi hole orifice.

From this study it is found that the scattering of the discharge coefficient would become serious, when the hole numbers are small enough, while discharge coefficient will increase and corresponding decrease of differential pressure when the numbers of holes are large enough.

Both the number of holes and their distribution have significant impact on the pressure drop and further on the discharge coefficient.

Download

Multi-hole orifice plate.pdf (1.1 MB)