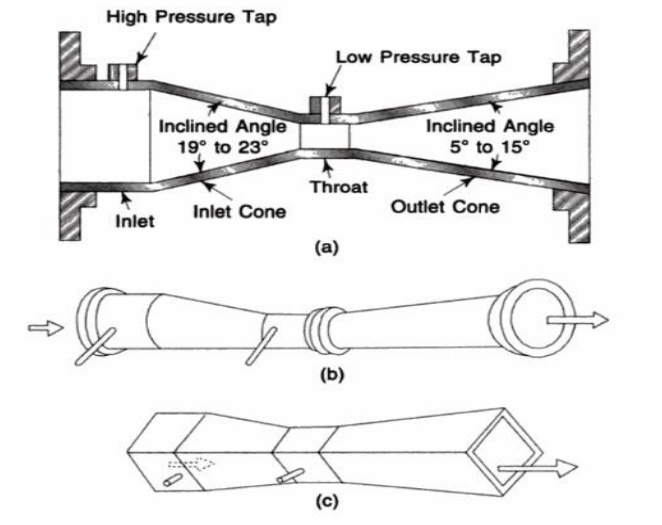

Venturi tube

Figures -

a) long-form or classic venture tube

b) Eccentric form

c) rectangular form

Construction:

A venturi tube is used where permanent pressure loss is of prime importance, and where maximum accuracy is desired in the measurement of high viscous fluids.

It consists of

-

a straight inlet section of the same diameter as the pipe in which the high pressure tap is located,

-

a converging conical inlet section in which the cross-section of the stream decreases and the velocity head and decrease of pressure head,

-

a cylindrical throat which provides for the low pressure tap location of the decreased pressure in an area where flow velocity is neither increasing nor decreasing, and

-

a diverging recovery cone in which velocity decreases and the decreased velocity head is recovered as pressure head, as shown in Figure 1.

The pressure taps are located one-quarter to one-half pipe diameter up-stream of the inlet cone and at the middle of the throat section.

Working:

-

The function of the different size cones is to produce differential pressure inside the tube, which can be connected to the secondary pressuremeasuring device.

-

This will measure the differential pressure produced by the tube. This pressure difference can be calibrated in terms of flow rate.

-

The venturi tube can be used to handle a fluid, which is handled by an orifice plate, and fluids that contains some solids, because these venturi tubes contain no sharp corners and do not project into the fluid stream.

-

It can be also used to handle slurries and dirty liquids that build up around other primary elements, if the pressure taps are protected from plugging.

The venturi tubes are usually made of cast iron or steel, and are built in several forms such as

(i) long-form or classic venturi tube.

(ii) short-form where the outlet cone is shortened,

(iii) an eccentric form to minimize the built up of heavy material and a

(iv) rectangular form used in air duct-work.

Advantages:

- Less chances of getting clogged with sediments.

- co-efficient of discharge is high.

- Its behavior can be predicted perfectly.

- Can be installed vertically, horizontally and inclined.

- They are more accurate and can be used for a wide range of flows.

- Around 90% of pressure drop can be recovered.

Disadvantages:

- They are large in size and hence where space is limited, they cannot be used.

- Higher initial cost, installation and maintenance.

- Require long laying length.

- Cannot be used in pipes below 7.5 cm diameter.

- Maintenance is not easy.

- Cannot be altered for measuring pressure beyond a maximum velocity.