Standard pressure gauges can not be used to measure liquid level in a cryogenic tank because of a number of issues.

Most importantly, is the fact that the tanks are pressurized (often upwards of 500psi) and standard pressure gauge mounted at the bottom would measure the liquid level plus the tank pressure.

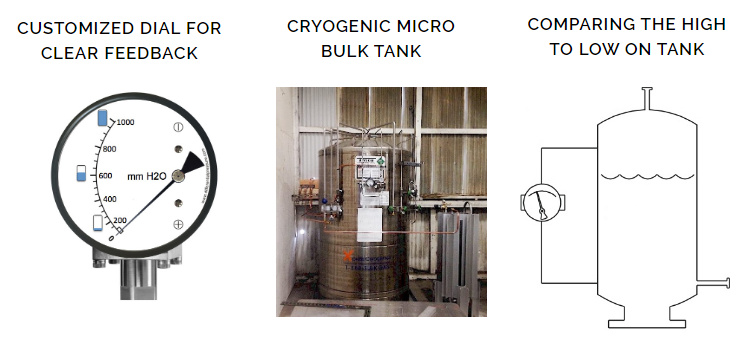

Consequently, a differential pressure gauge must be used by connecting the high side to the bottom of the tank and the low side to the top of the tank.

As a result, tanks measuring liquid oxygen, nitrogen, argon, and much more can have a cost effective solution to getting an inside look at their liquid levels.

These applications of differential pressure gauges for cryogenic liquid level can:

-

Provide direct feedback of liquid level in pressurized tank

-

Far more cost effective than ultrasonic, electronic transmitters, and other complex liquid level measurement instruments.

-

Provides added value to microbulk storage tanks