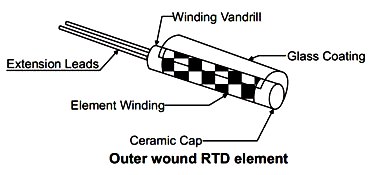

Outer wound RTD element

The outer wound RTD element is made by winding the sensing element wire around a center mandrill, which is usually made of ceramic. This winding is then coated with glass or some other insulating material to protect and secure the windings.

The winding wires are then spot welded to extension leads and secured to the body with ceramic cement or epoxy.

Each of the types has their advantages. The thin film is the least expensive to manufacture and also the most rugged. They can also be manufactured in very small sizes. The inner coil wire wound style is the most accurate.

It is however, more expensive to manufacture and does not perform well in high vibration applications. The outer wound element is similar in cost to the inner coil element. It is not as accurate as the inner coil style but is more rugged.