Earlier PLC were limited to discrete I/O interfaces, which allowed only ON / OFF type devices to be connected.

This limitation meant that the PLC Hardware Components could have only partial control of many process applications.

PLC Analog I/O modules

Today, however a complete range of both discrete and analog interfaces are available that will allow the controller to be applied to practically any type of the control process.

Analog input interface modules contain the circuitry necessary to accept analog voltage or current signals from analog field devices. These inputs are converted to digital by the use of an analog to digital converter (ADC).

The conversion value, which is proportional to the analog signal, is expressed as a 12 bit binary or as a 3-digit BCD for the use by the processor. Analog input sensing devices include temerature, light, speed, pressure and position transducers.

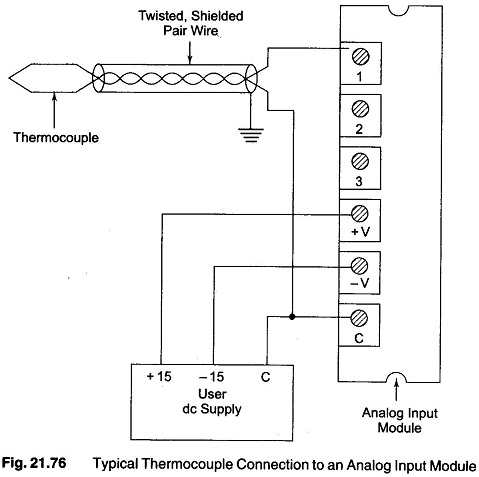

Figure 21.76 shows a typical analog input interface module connection to a thermocouple. A varying dc voltage in mV range proportional to the temperature being monitored, is produced by the thermocouple.

This voltage is then amplified and digitized by the analog input module and then sent to the processor on command from a program instruction.

Because of the low voltage level of the input signal, a shielded cable is used in wiring the circuit to reduce unwanted electrical noise signals that can be induced in the conductors from other wiring. This noise can cause temporary operating errors that can lead to hazardous or unexpected machine operation.

The analog output interface module receives from the processor digital data which is converted into a proportional voltage or current to control an analog field device. The digital data is passed through a DAC circuit to produce the necessary analog form.

Analog output devices include small motors, valves, analog meters and seven segment displays.