PLC Ladder Logic for Automatic Sorting Mixed Products

Control Purpose:

-

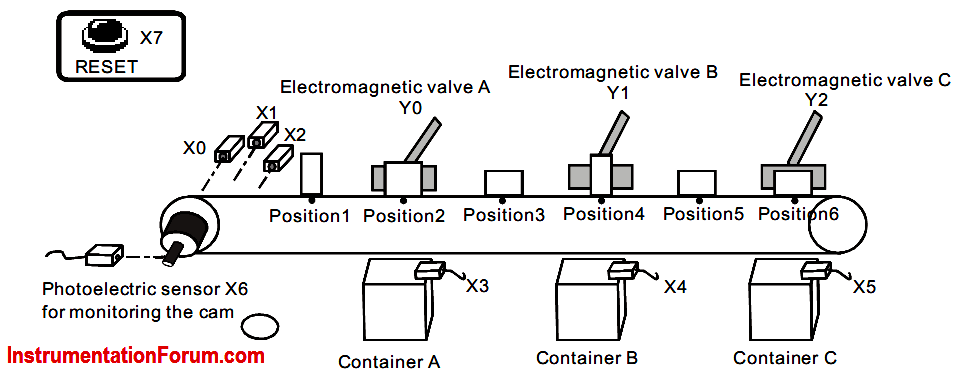

Sorting different products on the conveyor belt and pushing each product into its corresponding container.

-

There are three kinds of products, A, B and C and 6 positions for each product are set on the conveyor. Products will move forward for one position when the cam rotates once.

-

Sorting each product by product ID (Identification) sensors. Product A will be pushed in container A at position 2. And so forth, product B in container B at position 4; product C in container C at position 6.

-

When the product falling is confirmed by sensors, the electromagnetic valve will be reset. When RESET is pressed, all memory will be cleared and the system will restart the identifying and sorting process.

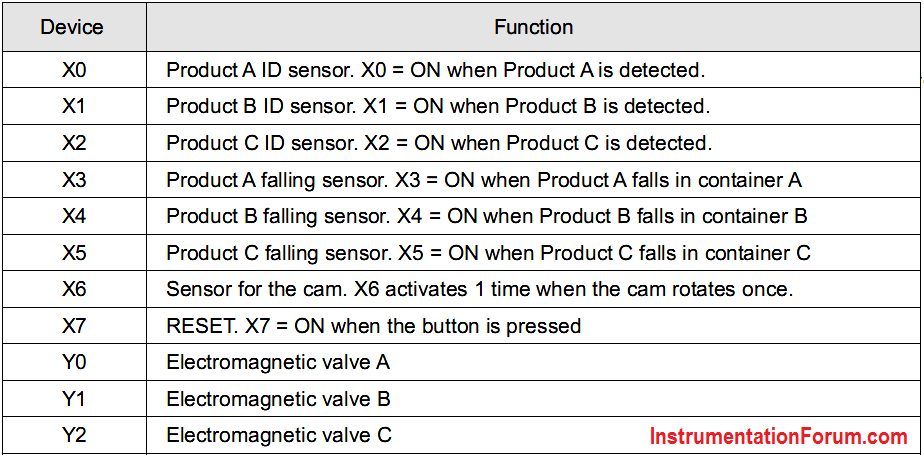

Devices:

Control Program:

Program Description:

-

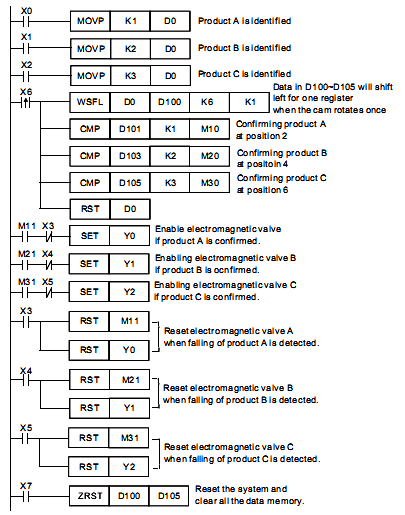

When product A is identified on the conveyor belt, X0 activates for one time to execute MOVP K1 D0 instruction. The value in D0 = K1. Likewise, when product B and C is on the conveyor, the value in D0 will be K2 and K3.

-

Products will move forward for one position when the cam rotates once. X6 activated one time to execute WSFL instruction. Data in D100~D105 will shift left for one register. At thesame time, CMP instructions will be executed to confirm product A at position 2 (D101), product B at position 4 (D103) and product C at position 6 (D105). After each CMP instruction, RST instruction will be executed to clear D0.

-

If product A , B or C is confirmed at position 2, 4 or 6, the corresponding M11, M21 or M31 will be ON to enable electromagnetic valve A, B or C to push the products in the containers.

-

When the falling of each product is detected by sensors, X3, X4 or X5 will be ON to reset electromagnetic valve A, B or C.

-

When RESET is pressed, X7 = ON to execute ZRST instruction. The value in D100~D105 will be 0, which means all data memory will be cleared.