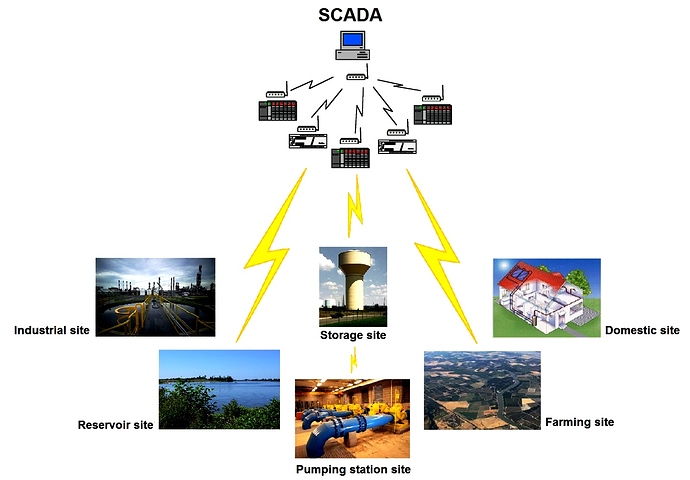

Supervisory Control and Data Acquisition or SCADA is a system used to monitor and control a plant or equipment in industries from a central location. It is a system, operating with coded signals over communication channels that provide control of remote equipment.

The major reason of its popularity in the manufacturing industry is that it significantly reduces operational costs and improves the performance of the plant. Training in SCADA enables managers, engineers, supervisors and operators to view and interact during the working of entire operations through graphical representation of their product process.

Several other benefits that a firm can have by adopting this advanced automation technology are:

- Increased life of the equipment being used by through immediate knowledge of system performance.

- Reduced labor costs required for troubleshooting or service.

- Increased compliance with regulatory agencies through automated report generating.

- No requirement of large capital investment.

- Many automation companies are using the SCADA to provide access to real-time data display, alarming, trending, and reporting from remote equipment.

- It gives the flexibility to choose equipment and systems based on performance rather than compatibility with installed base.

SCADA systems have made substantial progress over the recent years by penetrating into ancillary systems of cooling, ventilation, power distribution etc. and creating many job opportunities.