A Data Historian (also known as a Process Historian or Operational Historian) is a software program that records and retrieves production and process data by time; it stores the information in a time series database that can efficiently store data with minimal disk space and fast retrieval.

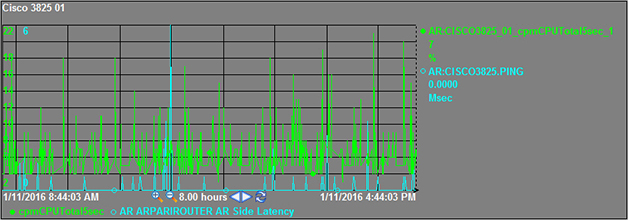

Time series information is often displayed in a trend or as tabular data over a time range (ex. the last day, last 8 hours, last year).

There are many uses for a Data Historian in different industries:

- Manufacturing site to record instrument readings

- Process (ex. flow rate, valve position, vessel level, temperature, pressure)

- Production Status (ex. machine up/down, downtime reason tracking)

- Performance Monitoring (ex. units/hour, machine utilization vs. machine capacity, scheduled vs. unscheduled outages)

- Product Genealogy (ex. start/end times, material consumption quantity, lot # tracking, product setpoints and actual values)

- Quality Control (ex. quality readings inline or offline in a lab for compliance to specifications)

- Manufacturing Costing (ex. machine and material costs assignable to a production)

- Utilities (ex. Coal, Hydro, Nucleur, and Wind power plants, transmission, and distribution)

- Data Center to record device performance about the server environment (ex. resource utilization, temperatures, fan speeds), the network infrastructure (ex. router throughput, port status, bandwidth accounting), and applications (ex. health, execution statistics, resource consumption).

- Heavy Equipment monitoring (ex. recording of run hours, instrument and equipment readings for predictive maintenance)

- Racing (ex. environmental and equipment readings for Sail boats, race cars)

- Environmental monitoring (ex. weather, sea level, atmospheric conditions, ground water contamination)

What can you record in a Data Historian?

It will record data over time from one or more locations for the user to analyze. Whether one chooses to analyze a valve, tank level, fan temperature, or even a network bandwidth, the user can evaluate its operation, efficiency, profitability, and setbacks of production. It can record integers (whole numbers), real numbers (floating point with a fraction), bits (on or off), strings (ex. product name), or a selected item from a finite list of values (ex. Off, Low, High).

Some examples of what might be recorded in a data historian include:

| Analog Readings: | temperature, pressure, flowrates, levels, weights, CPU temperature, mixer speed, fan speed |

|---|---|

| Digital Readings: | valves, limit switches, motors on/off, discrete level sensors |

| Product Info: | product id, batch id, material id, raw material lot id |

| Quality Info: | process and product limits, custom limits |

| Alarm Info: | out of limits signals, return to normal signals |

| Aggregate data: | average, standard deviation, cpk, moving average |

![Time Series databases are critical to the efficient storage and retrieval of historical data, but this time series data becomes far more powerful and accessible when it is connected to a asset or equipment hierarchy.]

Collects data from heterogeneous sources into a common platform for analysis

Information collected within a facility can come from many different types of sources including:

- PLCs (Programmable Logic Controllers) that control a finite part of the process (ex. one machine or one processing unit)

- DCS (Distributed Control System) that could control an entire facility

- Proprietary Instrument Interface (ex. Intelligent Electronic Devices): data delivered directly from an instrument instead of a control system (ex. Weighing system, clean-in-place skid).

- Lab Instrument (ex. Spectrophotometer, TOC Analyzer, Resonance Mass Measurement)

- Manual Data Entry (ex. an operator periodically walks the production line and records readings off manual gauges)

Allows for correlation of information

Over time

One of the more obvious strengths of a data historian is its ability to correlate data over time, which can include:

- Day shift vs. evening or night shift

- One crew vs. another

- One lot of raw material to another

- One continuous production run vs. another

- One season to another

Across areas and facilities

A data historian could be applied independently in one or more areas, but it can really show its worth when applied across an entire facility, many facilities in a department, and across departments within an organization. One could discover that a production problem’s root cause is insufficient brine supply to the production equipment or one could discover the 2 similar units produce significantly different results over time.

What types of questions does a Data Historian answer?

- How much time was this equipment running in the last 24 hours?

- How much fuel did this gas turbine consume during the last 8 hours?

- How many square feet of paper was produced yesterday?

- What was the average, maximum, and range of CPU temperatures over the summer?

- Was there a significant environmental release to the atmosphere last night with the XYZ valve failure?

- Does the use of #2 ball mills correlate with the increased carbon content in the ash at the coal power plant?

Visibility

Visibility can be at the single instrument level all the way up to an entire organization and beyond. The further you stand back from the process, the more you will see what you can benefit from a data historian.

- Monitor an instrument to keep it operational and to recognize the need for calibration, repair, or replacement

- Monitor a process, a set of equipment in a unit, to get it to operate within a set of process specifications

- Monitor batch production to allow for overlaying of ‘golden batches’ over suspect batch runs for comparison and analysis.

- Monitor production within a unit to maintain product quality within the process capability

- Monitor the entire production train for maximum operational efficiency and flow

- Monitor all aspects of the facility to optimize resource demand and consumption

- Monitor multiple facilities to strive for consistency and continuous improvement

- Monitor your vendors to control the quality and availability of your supply.

- Monitor customer usage of your product as it relates to how you produce it.

- Allow operational real-time data to integrate with business and financial systems.

- ‘Blackbox recorder’ functionality that can record information that isn’t looked at unless there is an incident.

- Provide input for designed experiments, prototype production systems, and continuous improvement initiatives.

Operational data that is well-organized and easily accessible can enable informed and fast decision making to improve productivity, quality, and efficiency at all levels of an organization. When it comes time to introduce a new product or substantially change an existing one, the process knowledge gained from a data historian can make all the difference between guessing that you can do it and knowing you can do it!

Examples where a Data Historian is useful

- Demand-driven manufacturing

- Plant and Building energy management

- Batch, Continuous, and Transitional manufacturing processes

- Corporate and Cloud Data Centers

Advantages of a Data Historian

Off-the-shelf data historians have several advantages over home grown systems and off-the-shelf relational databases:

- Off-the-shelf data acquisition interfaces with control systems, OPC compliant equipment, and intelligent electronic device (IED).

- Data acquisition redundancy, store and forward, and fail-over features

- High speed data collection (ex. 15,000 to 50,000 samples per second) with sub-second time resolution

- Efficient data storage through compression; filtering out of system noise and values that can be computed through interpolation.

- Simple archival storage in blocks of time instead of the monolithic structure of a relational database allows for 20 or 30 years of information to be available online.

- Data Security by role down to individual data point granularity

Maximize with a Hybrid: Data Historian and Relational Database

A data historian is not designed to efficiently handle relational data and relational databases are not designed to handle time series data. However if you can have a software package that offers both with the ability to integrate data from each different storage type, then you have a much more powerful solution.

Reference - automatedresults